Proposals for higher productivity: Vertical Spindle Rotary Surface Grinding Machine – SVR Series

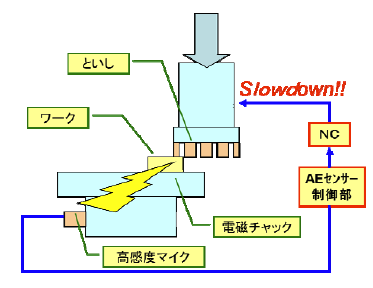

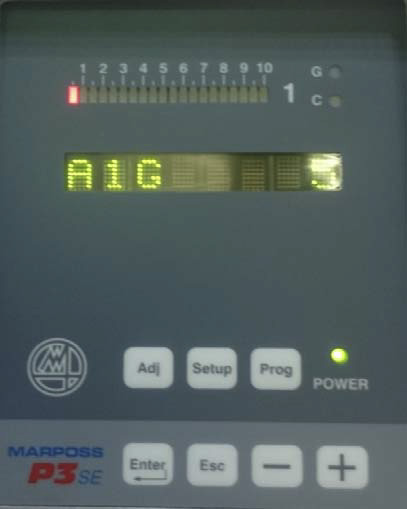

AE sensor

By detecting any contact of the workpiece with the grinding wheel with high sensitivity, various productivity factors can be improved.

AE Sensor for Contact of Grinding Wheel

Any contact of the workpiece with the grinding wheel can be detected with high sensitivity using the AE sensor, so it brings the following benefits:

- Prevents the excessive feed of grinding wheel that is difficult to check by sound or vision.

- Ensures surface quality by preventing the excessive feed of grinding wheel and controlling scratches.

- Detects workpieces that cannot be detected using the spark-on function with load detection method, so the cycle time is reduced and the productivity is improved.

Features

- High-sensitivity monitoring with acoustic emission technology.

- Can detect contact regardless of load.

- The sensitivity setting is easy to configure intuitively with a bar graph meter.

- The bar graph meter displays the status linearly while grinding.

- Can be used for the automatic detection of grinding wheel contact (spark-on function).

Combined use with the spark-on function

- Use together with the spark-on function with load detection method to achieve a higher level of safety and ease of mind with the automatic detection of grinding wheel contact.

- The burden on the operator is reduced, and it contributes greatly to multi-unit operation.

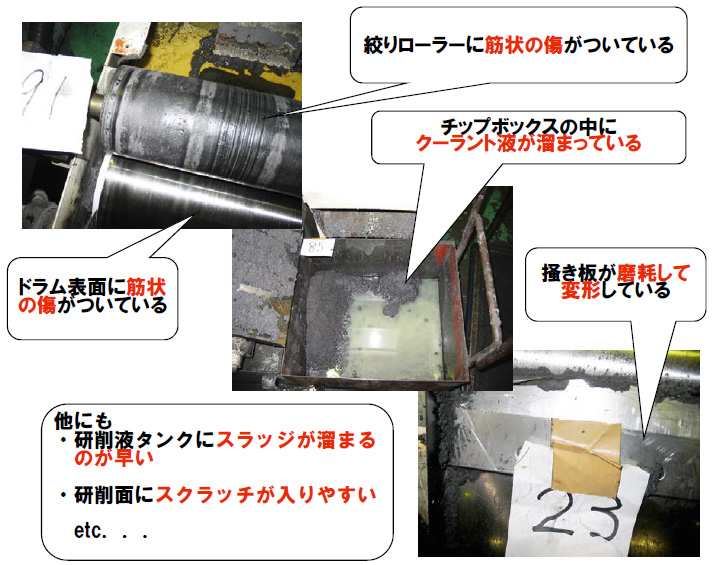

Magnet separator

Look at the back of the machine. Does your magnet separator look like the pictures shown below?

If so, why don’t you try upgrading to Sumitomo Heavy Industries Finetech’s FINE MAG, our best performing magnet separator?

We recommend the K model, which uses rare earth magnets!

- Equipped with a magnet drum with the most optimum design based on our unique

analytical technology for magnetic fields.

It has a high filtering performance that can be maintained for a long period of time. - Special hardening treatment for the magnetic drum surface.

The drum surface will not be scratched semi-permanently. - Adopted the forced drive method for the squeeze roller to prevent

slipping.

The sludge is squeezed strongly with stable pressure.

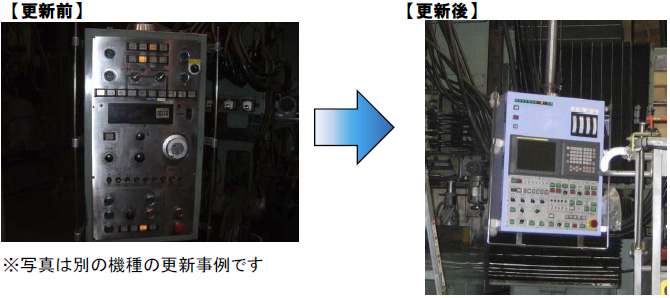

IoT

The system can now be integrated with IoT after the CNC device has been updated.

Integrate with IoT by updating to the latest CNC device, which is equipped with a network function as a standard. The addition of various operating information and sensors makes it possible for customers to monitor their operating status.

Let us know what you would like to manage using IoT.

- Improving the deterioration of processing precision due to a rise in the temperatures of the machine and peripheral systems.

- Early detection of vibrations and improving the deterioration of surface grinding quality as a result of grinding wheel unbalance and bearing abrasion.

- Managing coolant volume by detecting any drop in coolant level.

- Preventing the deterioration of processing precision by detecting any temperature anomaly in the coolant.

- Reducing downtime with machine breakdown alerts.

- Managing idle time with work completion notifications.

- Improving grinding efficiency by monitoring the current value of spindle.