Recommended Industry and Workpiece

Grinding machine Cutters T-dies and long cuttersGrinding machine Liquid crystal and semiconductor parts Glass and ceramics

Grinding machine Molds Mold plates

Grinding machine Molds Motor core molds and progressive molds

Grinding machine Various machine parts Linear motion guide

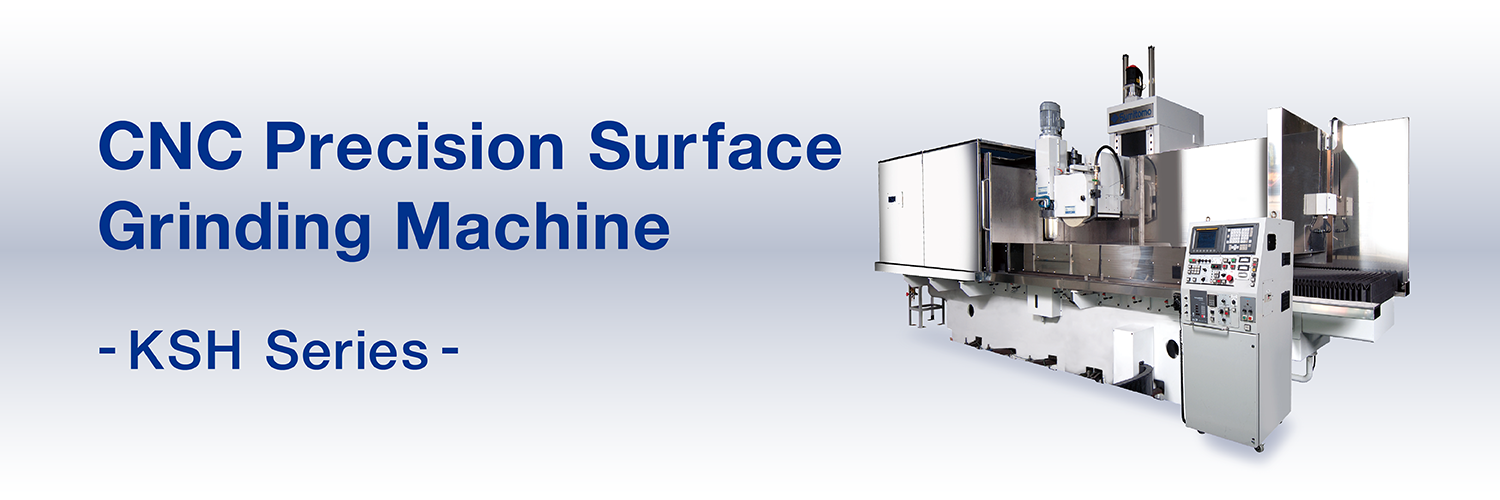

Product characteristics

Easy to operate

- The automatic cycle can be run by simply inputting the data on the interactive operation screen.

- A wide range of grinding software can be added depending on the customer’s usage purpose (optional accessory).

- Equipped with a graphic interactive input format for a fully automatic grinding function, including dressing cycle, as a standard.

- Compatible with customers’ proprietary programs as well.

Improved grinding precision

- Thermal displacement is controlled by cooling the grinding head.

- The appropriate peripheral speed can be set to grind various materials by adding a spindle inverter control device (optional accessory).

- A V-V mechanism is adopted for the table slideway to achieve a stable table turnaround operation.

- Magnetic chucks (optional accessories) can be added and selected.

Energy-saving, space-saving and clean

- All spindles are driven by servo motor to save energy.

- Saved energy and space by not using a hydraulic unit.

- Prepared special specifications to ensure a clean working environment by blocking the dispersion of coolant mist.

- Splash guard

- Sliding type

- Attached to the ceiling on the left

- Fully sealed type

- Stainless steel

- Dust collector

High-precision specifications (X series)

- The grinding head front/rear slideway uses the hydrostatic guide format.

- The spindle uses hydrostatic bearing.

- The grinding head is equipped with a hydraulic counterbalancer.

- The grinding head vertical feed and front/rear feed have full closed-loop control using linear scale.

Control panel and grinding software

- The control panel is built for simple operations.

- The teaching method is adopted for the simple settings of grinding conditions and the table reversing position settings via the interactive screen, so anyone can operate it easily.

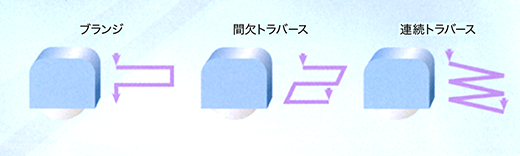

- Equipped with a fully automatic grinding software that includes layered grinding and double-sided grinding as a standard, in addition to rough/fine grinding and dressing cycle.

- A variety of programs can be added according to the customer’s usage purpose, such as crowning device, contouring function, and grinding wheel forming dressing function (optional accessories).

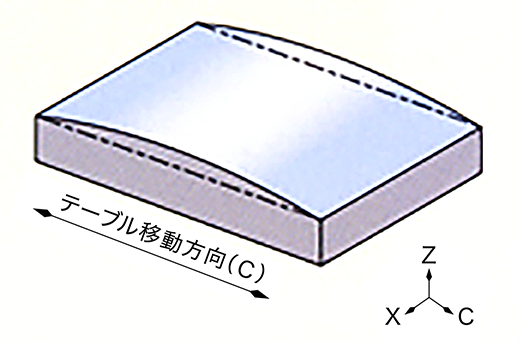

Z axis convex/concave grinding device (凸)

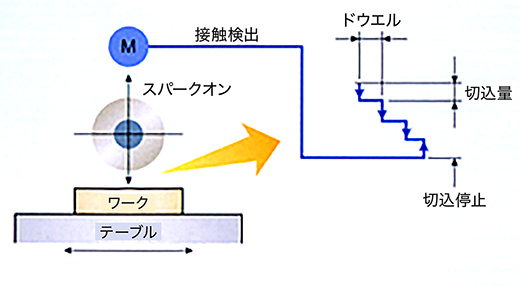

Spark-on control device(optional accessories)

This function helps to reduce the air cutting time and improve the actual operation rate.

The meter relay type or the high-sensitivity type can be selected depending on the characteristics of the workpieces to be ground.

Coolant processing equipment (optional accessory)

The coolant is essentially the blood of the grinding machine.

The coolant processing equipment is important, so we will introduce one that fits the customer’s usage purposes.

The FINE MAG magnetic separator is developed by our company.

Dynamic grinding wheel balancing device (optional accessory)

To ensure that the important grinding wheel is balanced on the machine, an interactive, fully automatic type (water balance type) or other types of dynamic grinding wheel balancing device can be added.

Vertical specifications (optional accessory)

By adding a vertical grinding head to the standard horizontal grinding head, the side and other parts can also be ground instead of just the top.

Case study

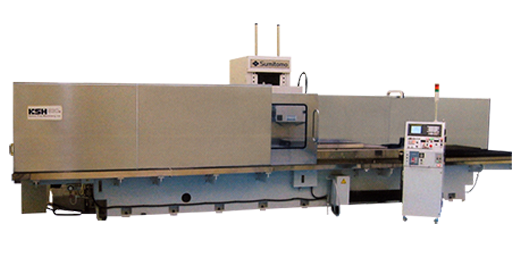

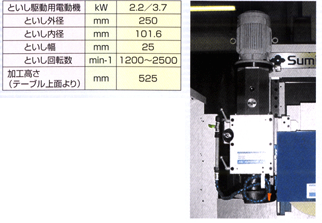

Product specifications

Specification

| Grinding width | 800 mm |

|---|---|

| Grinding length | 1500~5000 mm or more |

| Max. grinding height | 700 mm |

| Head automatic feed rate | 0.1~99 µm |

| Spindle drive motor(horizontal axis) | 7.5~15 kW |

Standard accessories

- CNC control equipment FANUC FS-0iM

- Grinding wheel(Ф510‐75mm)and flange

- Diamond tool with magnet base (can be fixed to processing upper right processing seat on table)

- Splash guard

- Wheel lifting tool

- Installation parts

- Power supply equipment

- Work light

- Leakage breaker

- Table top surface T groove

Optional accessories

- Coolant device

- Magnetic coolant separator

- Magnetic coolant separator with paper filter

- Centrifugation

- Cyclone separator, others

- Coolant temperature control device(standard, high precision)

- Magnetic chucks(various) and automatic neutrolator

- Spindle inverter control

- Spindle drive motor(15kW)

- Dynamic wheel balancing device

interactive system/coolant injection system - Automatic measuring device of grinding allowance

- Wheel flange (spare)

- Wheel balancing arber

- Cutting of T-slot on the table

- Spark-on control device

Meter relay type / high sensitivity type - Automatic overload retracting device

- Mist collector

- Splash cover

Slide type / Left ceiling / fully closed type / SUS type - Rotating lamp(3-color)

- Program storage length

160m/320m/640m - Automatic start or cut off device

- Convex/concave grinding device

- Contouring function

- Special grinding software

- The designated color

- Universal spindle head

- Spindle head / Vertical / Front / Back Static Guide

- Spindle static pressure bearing

- Coolant hose for table cleaning

- Integrated operation meter

- Rotary dresser(diamond/CBN)

- Spindle head over dresser

- Mold dressing