Recommended Industry and Workpiece

Coolant processing equipment Construction machines and construction machine parts Engine/TransmissionCoolant processing equipment Automotives/Automotive parts/Motorcycle parts Transmission/Gear/Gear Cutting

Product characteristics

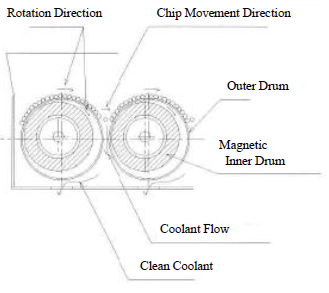

- Magnets are embedded eccentrically in the stainless steel roller. The rollers rotate in the same direction, allowing the chips to be transported efficiently.

- The dirty coolant travels through the gaps of the rollers and the chips adhere to them. They move along from one roller to another until they are finally discharged. Once the chips have been removed, the cutting fluid can be reused as clean coolant.

- The guide plate method is adopted, which reduces the coolant loss.

- Applicable for both wet and dry types.

Case study

- Gear cutting machines, broaching machines, etc.

- Magnetic chips from multiple spindle automatic machines and dedicated machines.

- For sludge, curls, and long chips, please contact us for more information.

※Cutting oil which is included in the chips is recyclable by using together with a centrifugal separator.

Product specifications

Specifications

| Model | RM1.5A | RM2A | RM3A | RM4A |

|---|---|---|---|---|

| Magnet roller width (mm) | 150 | 200 | 300 | 400 |

| Processing volume(L/min)※ | 30 | 40 | 60 | 80 |

| Max. chip length (mm) | 100 | 150 | 250 | 350 |

※For one pair of rollers if water soluble coolant is used. For oil-based coolant, please contact us.

Caution: Avoid mixing foreign objects because it may cause the machine to break down.

Outline Drawings