We provide the most optimum solution that can help customers resolve their issues according to their purpose and requirements.

Sumitomo Heavy Industries Finetech is highly regarded by our customers for the after-sales services we provide after delivering our products.

We want to provide a feeling of security so our customers will use our products for a long period of time.

From maintenance to adjusting the precision and handling troubles on-site, we have you covered.

For customers who are using Sumitomo’s grinding machines

Proposals for preventive maintenance

In recent years, many companies have experienced sudden equipment failures as they pushed for shorter

delivery period and higher quality in their workpieces.

Production equipment will definitely go through aging degradation after installation, so it is important for

customers to take preventive maintenance measures for their grinding machines in order the maintain their

performance and prevent breakdowns.

Proposals to improve functions

We offer solutions to improve functions and achieve higher productivity.

Proposals for machine overhaul

Taking apart a machine to “revive” it.

All machines experience aging degradation.

Operators have to continue using old machines while dealing with their lower precision and minor

breakdowns, which then lead to lower productivity.

Our company utilizes the know-how that we have accumulated over the years as a manufacturer to propose

overhauls according to the customer’s budget and work schedule.

Under the hands of our skilled workers, we revive the machines even as we take them apart.

For more information, please contact us using the Contact Form.

CASE Study of machine overhaul

Proposals to extend the machine life

For customers who are using dynamic bearing spindle

Creating a spindle unit for dynamic

bearing spindle

We have good news for our customers who are using dynamic bearing spindle!

There was a period of time when the KPL series (the previous version of the Double column Surface

Grinding Machine KSL series) adopted dynamic bearing spindle as horizontal spindle.

We have received complaints from KPL customers who are using dynamic bearing spindle regarding the

difficulty of maintaining their machines.

“We want those who consider KPL to be an important machine to continue using it for a long period of time.”

This led us to retrofit the machine with a spindle unit for dynamic bearing spindle.

We hope that

our customers will use this as a way to extend the life of the KPL machine that they are currently

using.

For more information, please contact us using the Contact Form.

We provide the most optimum solution that can help customers resolve their issues.

We provide the most optimum solution that can help customers resolve their issues.

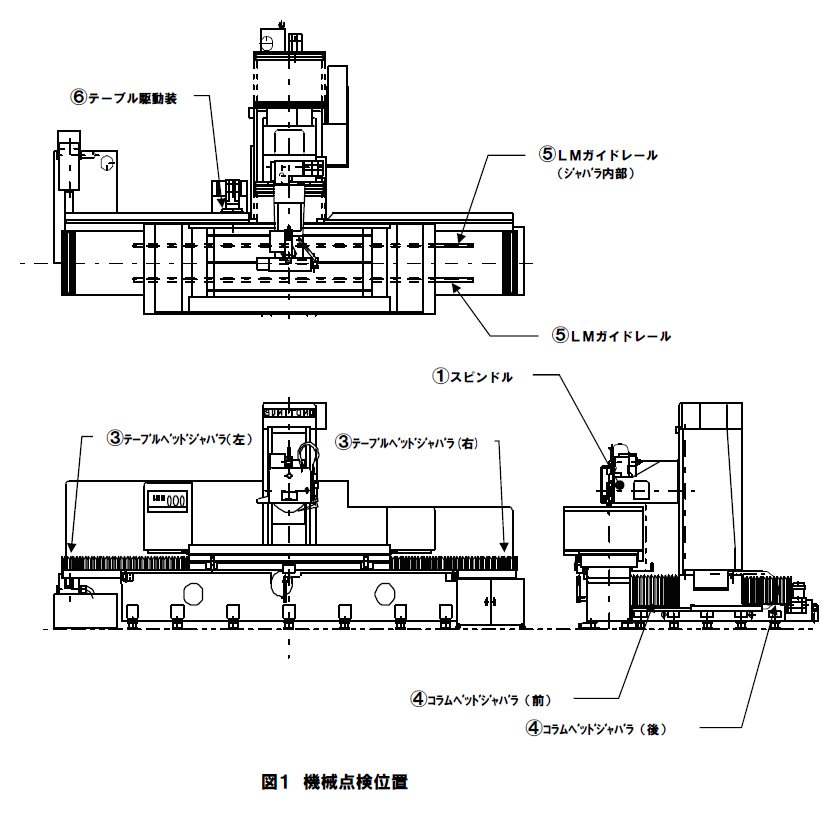

Proposals for preventive maintenance: CNC Precision Surface Grinding Machine – KSH Series

Self-diagnosis: Precision Surface Grinding Machine KSH Series self-diagnosis menu

Every part of the machine is a consumable, so it may degrade and be damaged. Using the machine under such circumstances may cause it to break down.

To prevent machine breakdowns, use the self-diagnosis menu to determine if it is necessary to replace or repair parts.

Inspection items

- Spindle

- Hydrostatic bearing spindle

- Bed bellows

- Column bed bellows

- Linear guides

- Table drive unit

If any of the following applies, a machine overhaul may be necessary.

First, please check each of the following items.

①Spindle

- The operation time has exceeded 10,000 hours.

- There is a strange noise when the spindle is rotating.

- It feels strange when it is rotated manually.

②Hydrostatic bearing spindle

- 20% or more of the pocket pressure is down compared to the start.

- The filter is clogged.

- There is abnormal heat generated.

- There is a strange noise when the Hydrostatic bearing spindle is rotating.

- It feels strange when it is rotated manually under hydrostatic pressure.

- The oil is dirty.

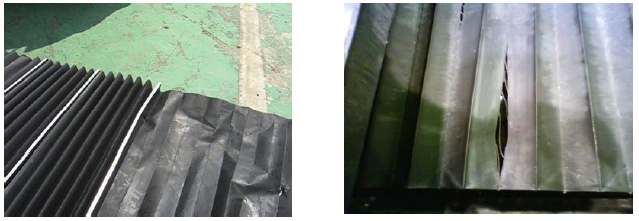

③Bed bellows (left and right)

- There is significant degradation.

- There is damage such as holes.

- It is bent.

④Column bed bellows (front and back)

- There is significant degradation.

- There is damage such as holes.

- It is bent.

The bellows is a consumable, so it may degrade and be damaged when used for a long period of

time.

Using the machine under such circumstances may cause coolant, waste, etc., to enter the bed

groove and cause the machine to break down.

Reference: Degraded/Bent/Damaged bellows

⑤Linear guides

- It feels strange when moving the table.

- Lubricating oil has not been applied to the linear guides. (No lubricating oil on the linear guides rail.)

- Rust has developed.

The Linear guides for guiding tables is hidden by the bellows, so it is not visible

usually.

As a result, operators may not notice any damage, which may lead to a major machine failure.

Reference: Scratched/Degraded Linear guidesrail

⑥Table drive unit

- There is a loud noise when it is reversed (sound of metal banging).

- There is a loud noise from the Speed reducer when the machine is running.

- The timing belt is undulated greatly when it is reversed.

Please contact us if any of the above applies.

Updating control devices that cannot be repaired

Some control devices installed in our grinding machines cannot be repaired after the production has stopped and the applicable service period has passed, even if they are broken. If a part of the device breaks down, the entire device needs to be replaced.

Some devices may take a while to prepare, so there is a risk that they may need to be stopped for a long period of time after they break down. As preventive maintenance, we recommend updating control devices before that happens.

The list below is an example of such devices. We can offer solutions individually if you have questions or requests.

List of control devices that cannot be repaired

| Model | Uses | Name | Model | Manufacturer |

|---|---|---|---|---|

| KSH | Control device for spindle drive | Inverter | FREQROL-A200(E) | Mitsubishi Electric |

| FREQROL-Z200 | ||||

| Control device for magnetic chucks | Contourator | NS2-5FE、NS2-10FET | Fuji Jikoh | |

| NS2-5FD | ||||

| NS2-5FC、NS2-10FC | ||||

| NS2-10GT1、NS2-20G |

Proposals for higher productivity: CNC Precision Surface Grinding Machine – KSH Series

Interactive dynamic wheel balancing device

Pursuit of complete ease-of-use and low cost

The definitive grinding wheel balance

Balancer for precision grinding

Field Balancer For High-Precision

SB-8001GS

(Max 10,000min-1)

Comes in an A4-sized trunk case!

The grinding wheel is rotated on the machine and measured, so it brings the following

benefits:

・Corrects any unbalance in the grinding wheel as a whole.

・Stabilizes the grinding resistance and improves the quality of the ground surface.

Features

- Extremely high measurement accuracy (resolution of 0.001 μm).

- Easy to operate because it is 2 or 3 weight selection type

- Easy to see with a large LED display.

- Weight angles and displacements are displayed in real-time.

- Compact, lightweight, and low cost (stored in a trunk case).

New functions

- Improved measurement accuracy with the installation of the latest

microcomputer.

The measurement accuracy for unbalanced vibration is higher compared to regular machines, making it possible to correct unbalances with a high precision at a high decreasing rate. - The angle scale (increase/decrease in the direction of the rotation) can be

selected.

The direction of the angle scale of the rotating device can be changed with one touch. - Equipped with a backup function.

Even when the power is turned off, the system remembers the influence coefficient and various settings (such as the number of correction plane and angle scale), eliminating the hassle of reconfiguring the system again.

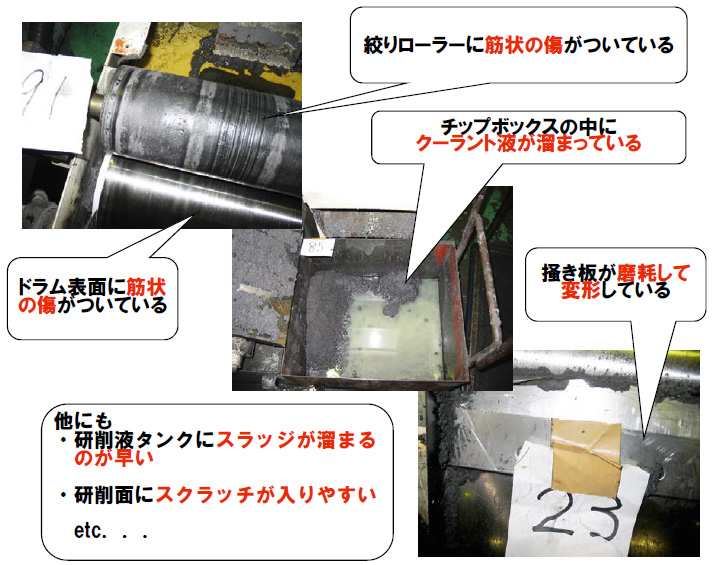

Magnet separator

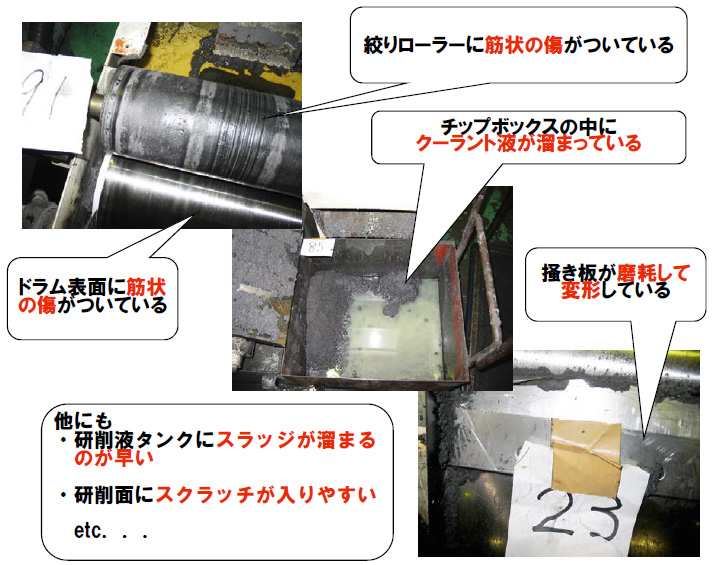

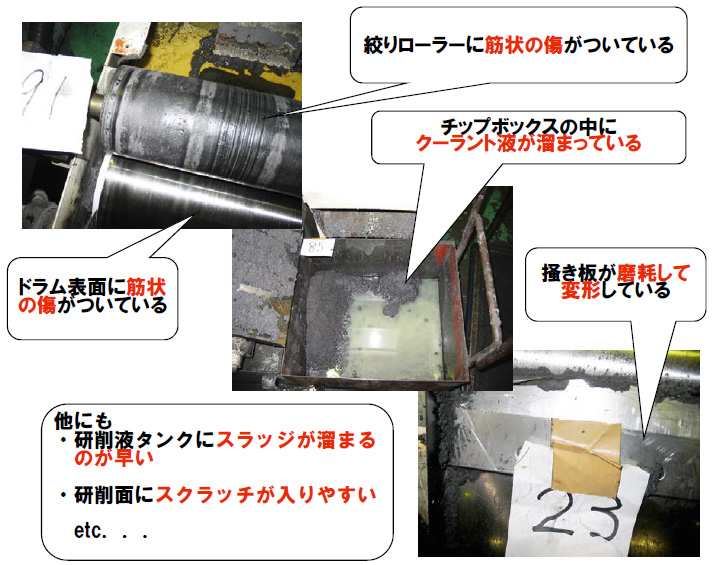

Look at the back of the machine. Does your magnet separator look like the pictures shown below?

If so, why don’t you try upgrading to Sumitomo Heavy Industries Finetech’s FINE MAG, our best performing magnet separator?

We recommend the K model, which uses rare earth magnets!

- Equipped with a magnet drum with the most optimum design based on our unique

analytical technology for magnetic fields.

It has a high filtering performance that can be maintained for a long period of time. - Special hardening treatment for the magnetic drum surface.

The drum surface will not be scratched semi-permanently. - Adopted the forced drive method for the squeeze roller to prevent

slipping.

The sludge is squeezed strongly with stable pressure.

IoT

The system can now be integrated with IoT after the CNC device has been updated.

Integrate with IoT by updating to the latest CNC device, which is equipped with a network function as a standard. The addition of various operating information and sensors makes it possible for customers to monitor their operating status.

Let us know what you would like to manage using IoT.

- Improving the deterioration of processing precision due to a rise in the temperatures of the machine and peripheral systems.

- Early detection of vibrations and improving the deterioration of surface grinding quality as a result of grinding wheel unbalance and bearing abrasion.

- Managing coolant volume by detecting any drop in coolant level.

- Preventing the deterioration of processing precision by detecting any temperature anomaly in the coolant.

- Reducing downtime with machine breakdown alerts.

- Managing idle time with work completion notifications.

- Improving grinding efficiency by monitoring the current value of spindle.

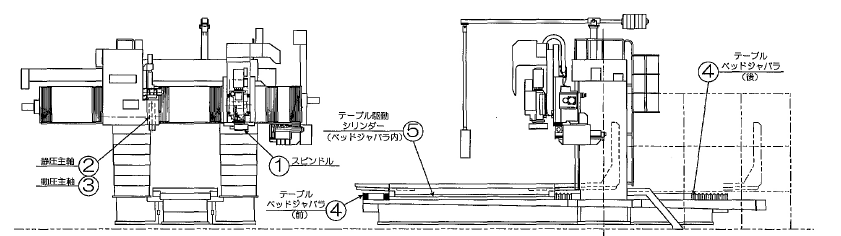

Proposals for preventive maintenance: CNC Double column Surface Grinding Machine – KSL Series

Self-diagnosis: KSL series self-diagnosis menu

Every part of the machine is a consumable, so it may degrade and be damaged. Using the machine under such circumstances may cause it to break down.

To prevent machine breakdowns, use the self-diagnosis menu to determine if it is necessary to replace or repair parts.

Inspection items

- Spindle(KSL-F: Bearing specification)

- Hydrostatic bearing spindle (KSL-F: Hydrostatic bearing specifications)

- Dynamic bearing spindle (KPL: Dynamic bearing only)

- Bed bellows

- Cylinder for table driving

If any of the following applies, a machine overhaul may be necessary.

First, please check each of the following items.

Note 1: For KPL users, check item 2. if spindle has hydrostatic bearing and item 3. if it has dynamic bearing .

Note 2: For KPL users, check item 1. if spindle is bearing and item 2. if it has hydrostatic bearing. Check items 4 and 5 regardless of the machine type.

①Spindle (KSL-F: Bearing specifications)

- The operation time has exceeded 10,000 hours.

- There is a strange noise when the spindle is rotating.

- It feels strange when it is rotated manually.

②Hydrostatic bearing spindle (KSL-F: Hydrostatic bearing specifications)

- 20% or more of the pocket pressure is down compared to the start.

- The filter is clogged.

- There is abnormal heat generated.

- There is a strange noise when the Hydrostatic bearing spindle is rotating.

- It feels strange when it is rotated manually under hydrostatic pressure (scraping, changes in weight, etc.)

- The oil is dirty.

③Dynamic bearing spindle (KPL: Dynamic bearing specifications only)

- The free running time differs. (15 seconds or so is normal; 9 seconds and below is considered abnormal.)

- The filter is clogged.

- There is a strange noise when the Hydrostatic bearing spindle is rotating.

- It feels strange when it is rotated manually under dynamic pressure.

- The oil is dirty.

④Bed bellows (front and back)

- There is significant degradation.

- There is damage such as holes.

- It is bent.

The bellows is a consumable, so it may degrade and be damaged when used for a long period of

time.

Using the machine under such circumstances may cause coolant, waste, etc., to

enter the bed groove and cause the machine to break down.

⑤Cylinder for table driving

- It feels strange when moving the table.

- Oil is leaking near the cylinder.

The cylinder is hidden by the bellows, so it is not visible usually.

As a result, operators may not notice any damage, which may lead to a major machine failure.

Please contact us if any of the above applies.

Updating control devices that cannot be repaired

Some control devices installed in our grinding machines cannot be repaired after the production has stopped and the applicable service period has passed, even if they are broken. If a part of the device breaks down, the entire device needs to be replaced.

Some devices may take a while to prepare, so there is a risk that they may need to be stopped for a long period of time after they break down. As preventive maintenance, we recommend updating control devices before that happens.

The list below is an example of such devices. We can offer solutions individually if you have questions or requests.

List of control devices that cannot be repaired

| Model | Uses | Name | Model | Manufacturer |

|---|---|---|---|---|

| KPL KSL KSL-F |

Wheel balancing device | Water balancer | Hydrokompenser HK-5000 | Hofmann |

| Control device for table drive | DC motor drive unit | DL-SBZ | Mitsubishi Electric | |

| LEOPAC-III | Toshiba | |||

| Control device for table drive Control device for spindle drive |

AC spindle drive unit | FRENIC5000V3 | Fuji Electric | |

| FRENIC5000V2MKII | ||||

| FRENIC5000V2 | ||||

| Control device for spindle drive Control device for rotary dresser drive Control device for AWC travel |

Inverter | FREQROL-A200 (E) | Mitsubishi Electric | |

| FREQROL-2200 | ||||

| FREQROL-2024 | ||||

| FREQROL-K400 | ||||

| FREQROL-K3 | ||||

| Control device for spindle head travel | Fine roll | FL750 | Mitsubishi Electric | |

| FL1500 |

Proposals for higher productivity: CNC Double column Surface Grinding Machine – KSL Series

Interactive dynamic wheel balancing device

Pursuit of complete ease-of-use and low cost

The definitive grinding wheel balance

Balancer for precision grinding

Field Balancer For High-Precision

SB-8001GS

(Max 10,000min-1)

Comes in an A4-sized trunk case!

The grinding wheel is rotated on the machine and measured, so it brings the following

benefits:

・Corrects any unbalance in the grinding wheel as a whole.

・Stabilizes the grinding resistance and improves the quality of the ground surface.

Features

- Extremely high measurement accuracy (resolution of 0.001 μm).

- Easy to operate because it is 2 or 3 weight selection type

- Easy to see with a large LED display.

- Weight angles and displacements are displayed in real-time.

- Compact, lightweight, and low cost (stored in a trunk case).

New functions

- Improved measurement accuracy with the installation of the latest

microcomputer.

The measurement accuracy for unbalanced vibration is higher compared to regular machines, making it possible to correct unbalances with a high precision at a high decreasing rate. - The angle scale (increase/decrease in the direction of the rotation) can be

selected.

The direction of the angle scale of the rotating device can be changed with one touch. - Equipped with a backup function.

Even when the power is turned off, the system remembers the influence coefficient and various settings (such as the number of correction plane and angle scale), eliminating the hassle of reconfiguring the system again.

Warning system menu

Coolant flow monitoring system

It is very dangerous to perform grinding when there is no coolant, because it may lead to fire accidents.

The surface grinding machines that we produce are equipped with a high-sensitivity flow sensor, which monitors the coolant flow while grinding. If the coolant stops flowing, the system can raise an alarm and stop the machine.

This eliminates the risk of fire accidents and operators can use the machine safely.

Current status

Has no flow sensor or has a paddle-type flow sensor

The paddle-type breaks down easily,

so it may not be functioning properly.

Manufactured by Yamatake:FS4-3J and FS7-4J

Our proposal

Installation of a high-sensitivity flow sensor

- The sensitivity is easy to adjust.

- Easy to maintain.

- Long life.

Manufactured by Ifm electronic: SI5000

| Target model | KPL/KSL/KSL-F | KSH |

|---|---|---|

| Target production number | FFK380〜TTK422 | FFH359〜TTH399 |

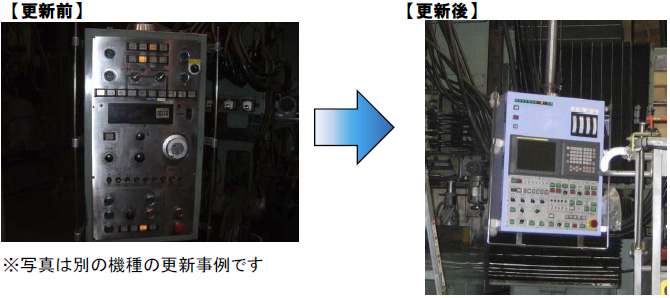

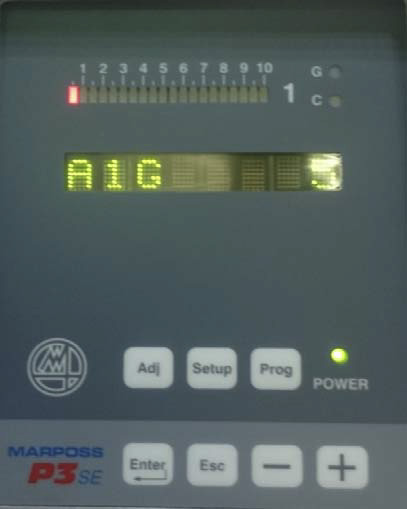

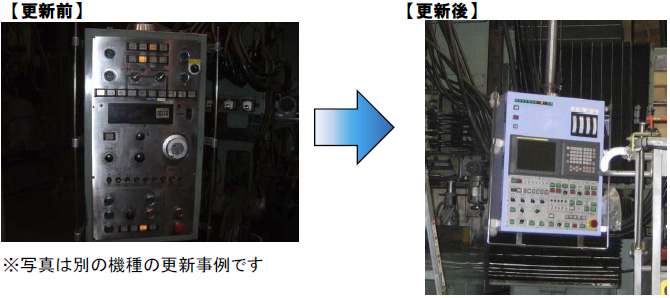

Why don’t you update your NC control device for a stable operation?

- Reduce the failure rate and increase the operating rate by updating your current NC control device.

- Our stable service parts supply system allows customers to use our products without worry even in the case of an emergency.

- The control panel has been renewed as well, so the operability has improved greatly.

- The ladder screen can be displayed, which reduces the time taken to track the cause of troubles.

Case Study of NC update

(1) KPL-2050N manufactured in 1987

· Updated in October 2007

· Updated the NC from FANUC FS12M to FANUC FS16iM.

(2) KPL-2070N manufactured in 1981

· Updated in December 2008

· Updated the NC from NEDAC to FANUC FS31iM.

Magnet separator

Look at the back of the machine. Does your magnet separator look like the pictures shown below?

If so, why don’t you try upgrading to Sumitomo Heavy Industries Finetech’s FINE MAG, our best performing magnet separator?

- Equipped with a magnet drum with the most optimum design based on our unique

analytical technology for magnetic fields.

It has a high filtering performance that can be maintained for a long period of time. - Special hardening treatment for the magnetic drum surface.

The drum surface will not be scratched semi-permanently. - Adopted the forced drive method for the squeeze roller to prevent

slipping.

The sludge is squeezed strongly with stable pressure.

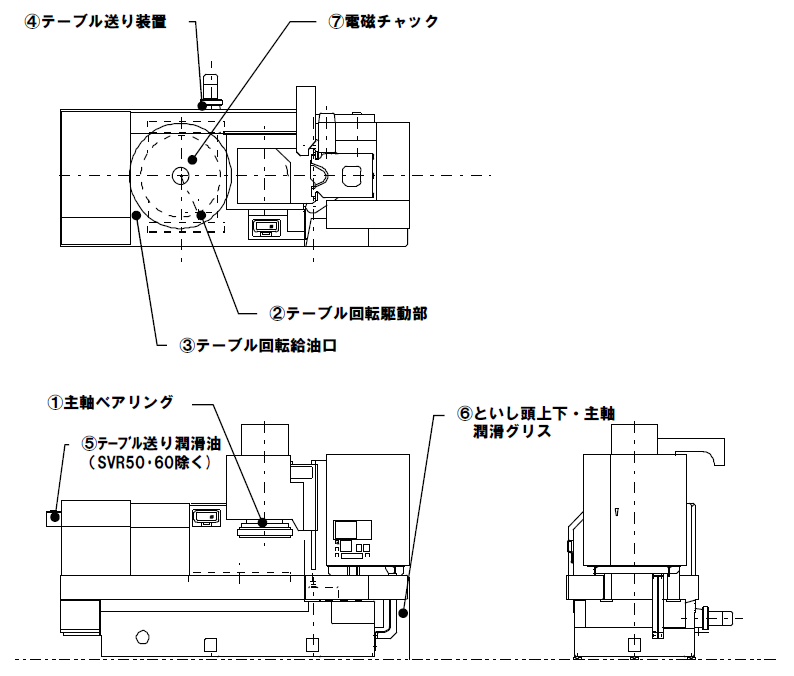

Proposals for preventive maintenance: Vertical Spindle Rotary Surface Grinding Machine – SVR Series

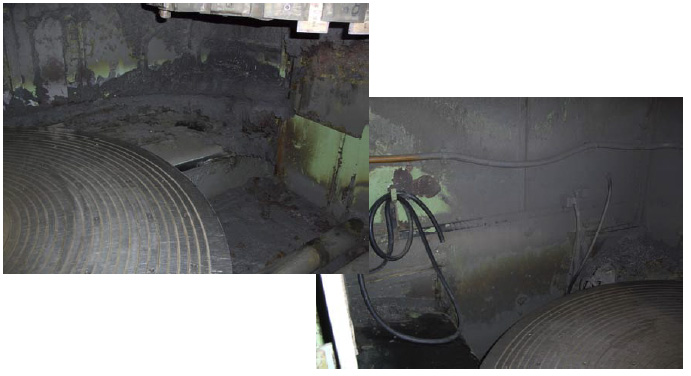

Please clean the machines after use every day so they will have a long life.

Chips and grinding wheel scraps from grinding work will adhere to the machine if they are left for a long period of time. In some cases, it may cause the machine to break down.

Simply cleaning the table with a hose after work every day can improve the machine life.

If left unattended like in the pictures below…

A few extra days will be needed just to scrape the machine clean during repair.

To reduce the machine stop time and repair fees, please clean the machines diligently every

day.

Do not forget to take safety precautions!

Self-diagnosis: Vertical Spindle Rotary Surface Grinding Machine SVR Series self-diagnosis menu

Every part of the machine is a consumable, so it may degrade and be damaged. Using the machine under such circumstances may cause it to break down.

To prevent machine breakdowns, use the self-diagnosis menu to determine if it is necessary to replace or repair parts.

Inspection items

- Spindle bearing

- Table rotation drive

- Table rotation lubricating oil inlet

- Table feed equipment

- Table feed lubricating oil

- Grinding head vertical feed and spindle lubricating grease

- Magnetic chuck

If any of the following applies, the machine may be close to breaking down even if it is still running.First, please check each of the following items.

①Spindle bearing

- There is a strange noise when the Hydrostatic bearing spindle is rotating.

- It feels strange when it is rotated manually.

- There is a strange noise and vibrations when grinding a workpiece.

②Table rotation drive

③Table rotation lubricating oil inlet

- There is a strange noise and vibrations when the table is rotating.

- The motor thermal protection for table rotation falls off frequently.

- There is a strange noise from the Cyclo speed reducer for table rotation.

- The lubricating oil has not been changed for a while. (There are two inlets at the top and bottom.)

④Table feed equipment

- There is rattling during table foward/backward feed.

- Lubricating oil is not applied to the table front/rear feed slideway. (Inspect by touch.)

- Sludge has accumulated on the table front/rear feed slideway. (Inspect by touch.)

- The motor thermal protection for table front/rear feed falls off frequently.

- There is a strange noise from the cyclo reduction gear for table front/rear feed.

- Sludge has accumulated on the rack and pinion drive system. (Inspect by touch.)

⑤Table feed lubricating oil

⑥Grinding head vertical feed and principle spindle

lubricating grease

- The lubricating oil or grease does not decrease.

⑦Magnetic chuck

- There is a large scratch and dent on the top surface of the magnetic chuck.

- The adsorption power of the magnetic chuck has dropped compared to the beginning.

- The demagnetizing ability of the magnetic chuck has dropped compared to the beginning.

Abnormalities will start to appear before a machine breaks down. They may turn out to be minor issues if detected early, but they can cause secondary or tertiary breakdown if detected late, so it is important to take note of the condition of the machine when using it.

Please contact us if any of the above applies.

Updating control devices that cannot be repaired

Some control devices installed in our grinding machines cannot be repaired after the production has stopped and the applicable service period has passed, even if they are broken. If a part of the device breaks down, the entire device needs to be replaced.

Some devices may take a while to prepare, so there is a risk that they may need to be stopped for a long period of time after they break down. As preventive maintenance, we recommend updating control devices before that happens.

The list below is an example of such devices. We can offer solutions individually if you have questions or requests.

List of control devices that cannot be repaired

| Model | Uses | Name | Model | Manufacturer |

|---|---|---|---|---|

| SVR | Table rotation (including some spindle rotation) | Inverter | AF-500 series | Sumitomo Heavy Industries |

| AF-1200 series | ||||

| AF-3000 series | ||||

| AF-3100、3100α series | ||||

| SF-320 series | ||||

| HF-320 series | ||||

| HF-420 series | ||||

| FVR-G7S series | Fuji Electric | |||

| FVR-C9S series | ||||

| FREQROL-A200 series | Mitsubishi Electric | |||

| FREQROL-A500L series | ||||

| HI series | Keyence | |||

| Table feed | Inverter | SF-320 series | Sumitomo Heavy Industries | |

| HI series | Keyence | |||

| Control device for magnetic chucks | Contourator | NS2-5FC、NS2-10FC | Fuji Jikoh | |

| NS2-5FE、NS2-5FET18 | ||||

| NS2-10GT1 | ||||

| NS4-10T4 |

Proposals for higher productivity: Vertical Spindle Rotary Surface Grinding Machine – SVR Series

AE sensor

By detecting any contact of the workpiece with the grinding wheel with high sensitivity, various productivity factors can be improved.

AE Sensor for Contact of Grinding Wheel

Any contact of the workpiece with the grinding wheel can be detected with high sensitivity using the AE sensor, so it brings the following benefits:

- Prevents the excessive feed of grinding wheel that is difficult to check by sound or vision.

- Ensures surface quality by preventing the excessive feed of grinding wheel and controlling scratches.

- Detects workpieces that cannot be detected using the spark-on function with load detection method, so the cycle time is reduced and the productivity is improved.

Features

- High-sensitivity monitoring with acoustic emission technology.

- Can detect contact regardless of load.

- The sensitivity setting is easy to configure intuitively with a bar graph meter.

- The bar graph meter displays the status linearly while grinding.

- Can be used for the automatic detection of grinding wheel contact (spark-on function).

Combined use with the spark-on function

- Use together with the spark-on function with load detection method to achieve a higher level of safety and ease of mind with the automatic detection of grinding wheel contact.

- The burden on the operator is reduced, and it contributes greatly to multi-unit operation.

Magnet separator

Look at the back of the machine. Does your magnet separator look like the pictures shown below?

If so, why don’t you try upgrading to Sumitomo Heavy Industries Finetech’s FINE MAG, our best performing magnet separator?

We recommend the K model, which uses rare earth magnets!

- Equipped with a magnet drum with the most optimum design based on our unique

analytical technology for magnetic fields.

It has a high filtering performance that can be maintained for a long period of time. - Special hardening treatment for the magnetic drum surface.

The drum surface will not be scratched semi-permanently. - Adopted the forced drive method for the squeeze roller to prevent

slipping.

The sludge is squeezed strongly with stable pressure.

IoT

The system can now be integrated with IoT after the CNC device has been updated.

Integrate with IoT by updating to the latest CNC device, which is equipped with a network function as a standard. The addition of various operating information and sensors makes it possible for customers to monitor their operating status.

Let us know what you would like to manage using IoT.

- Improving the deterioration of processing precision due to a rise in the temperatures of the machine and peripheral systems.

- Early detection of vibrations and improving the deterioration of surface grinding quality as a result of grinding wheel unbalance and bearing abrasion.

- Managing coolant volume by detecting any drop in coolant level.

- Preventing the deterioration of processing precision by detecting any temperature anomaly in the coolant.

- Reducing downtime with machine breakdown alerts.

- Managing idle time with work completion notifications.

- Improving grinding efficiency by monitoring the current value of spindle.