The two-head system allows the vertical rotary surface grinding machine to do single-pass grinding, rough processing using one chuck, and finish grinding.

- For the ascent/descent of the spindle, the servo motor is connected to the ball screws using a harmonic drive in order to create an ultra-precision rapid traverse mechanism with close to zero backlash.

- The spindle axis is maintained at a right angle to the table surface by using the three-point instruction system for the table that is easy to operate.

- Achieved the smallest installation space possible with a new design.

- The load of the spindle and column (sliding part) against the ascent/descent slide is greater than regular machines, so it is more balanced and can handle a variety of grinding work from ultra-precision grinding to heavy grinding.

- The magnetic chucks control thermal changes, so it has forced-air cooling. The top part is injected with cermet to minimize the drop of magnetic force, maintain high precision and attach/remove workpieces easily.

- The dual axis structure makes it possible to complete rough and finish grinding with just one chucking, so high-mesh grinding (#1000 to #4000) can also be done.

- The grinding process can be controlled in four stages with the CNC control. The correction of grinding wheel abrasion can be done individually or as a simple one-time work. We can also provide a control program based on the user’s request.

Recommended Industry and Workpiece

Grinding machine

Automobiles/Automobile parts/Two-wheel parts

Connecting rods for automobiles - Automated systems

Grinding machine

Liquid crystal and semiconductor parts

Rough/finish grinding

Grinding machine

Optical glass/Optical parts

Optical parts and rough/finish grinding

Grinding machine

Electrical and electric equipment parts

Electric equipment parts and rough/finish/mirror grinding

Grinding machine

Various machine parts

Bearings - Rough/finish - Automated systems

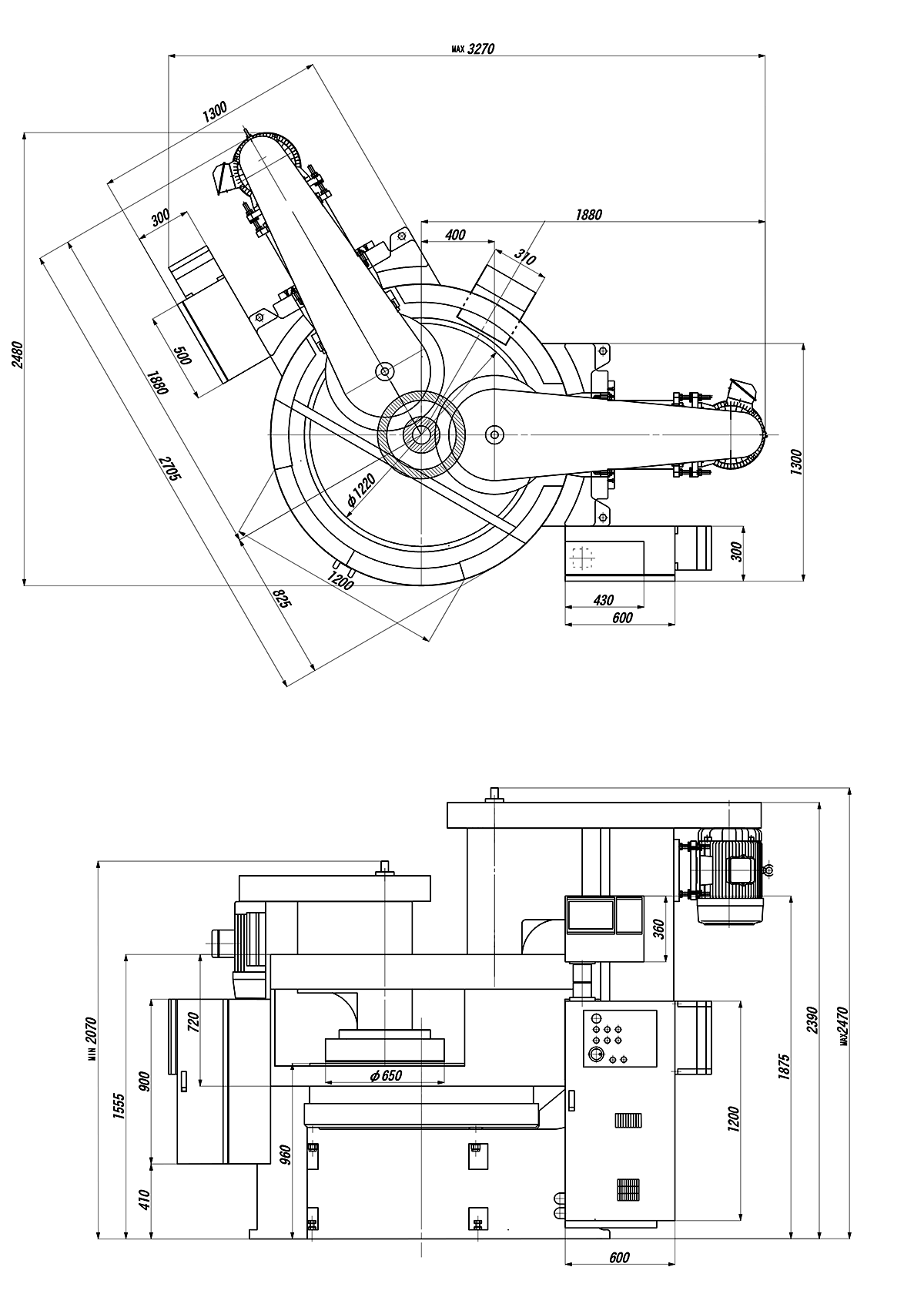

Product specifications

| Model specifications: |

1200 dual axis CNC |

| Max. height of workpiece |

350mm |

| Swing diameter of workpiece |

φ1250xφ250mm |

| Magnetic chuck diameter |

φ1220mm |

| Grinding wheel diamond external diameter |

φ450mm |

| Table rotations |

2-25 min-1 |

| Spindle rotations |

750 min-1; variable inverter |

| Feed rate |

0.01mm/min |

| Spindle rapid ascent/descent rate |

100mm/min |

| Motor used |

For main spindle |

30kw 4P |

| For table |

5.5kw gear motor |

Spindle control

(Feed) |

AC servo motor |

Spindle control

(Rapid traverse) |

| Coolant pump |

3φ 400W 2P |

| Machine dimensions |

Length |

2930mm |

| Width |

3270mm |

| Height |

2470mm |

| Machine weight |

12,000kg |

Dimension of machine size

Visitors who viewed this item also viewed

read more

Model UK has been added to our famous FINE Mag series, which has the greatest attracting power ever.