Recommended Industry and Workpiece

Grinding machine Liquid crystal and semiconductor parts Glass and ceramicsGrinding machine Various machine parts Various machine parts (Various flat plate parts)

Grinding machine Molds Steel and mold plates

Grinding machine Machine tools Machine tool frame manufacturing

Grinding machine Optical glass/Optical parts Measuring instrument - Stone plate/Glass

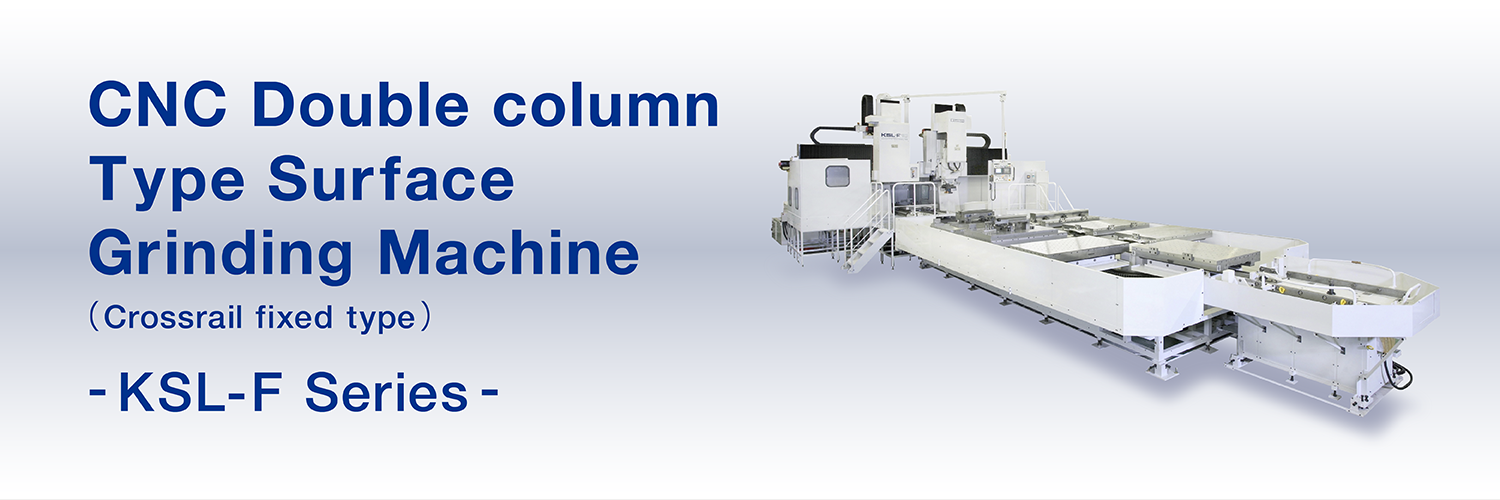

Product characteristics

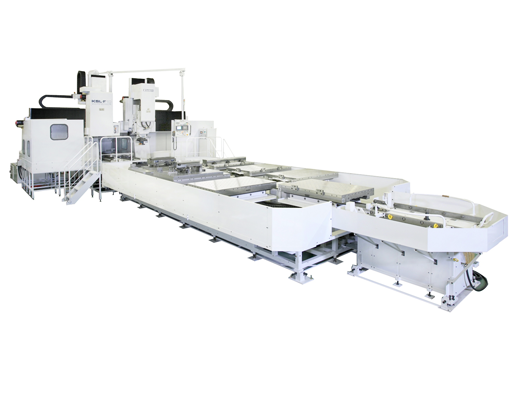

Compact and economy machine

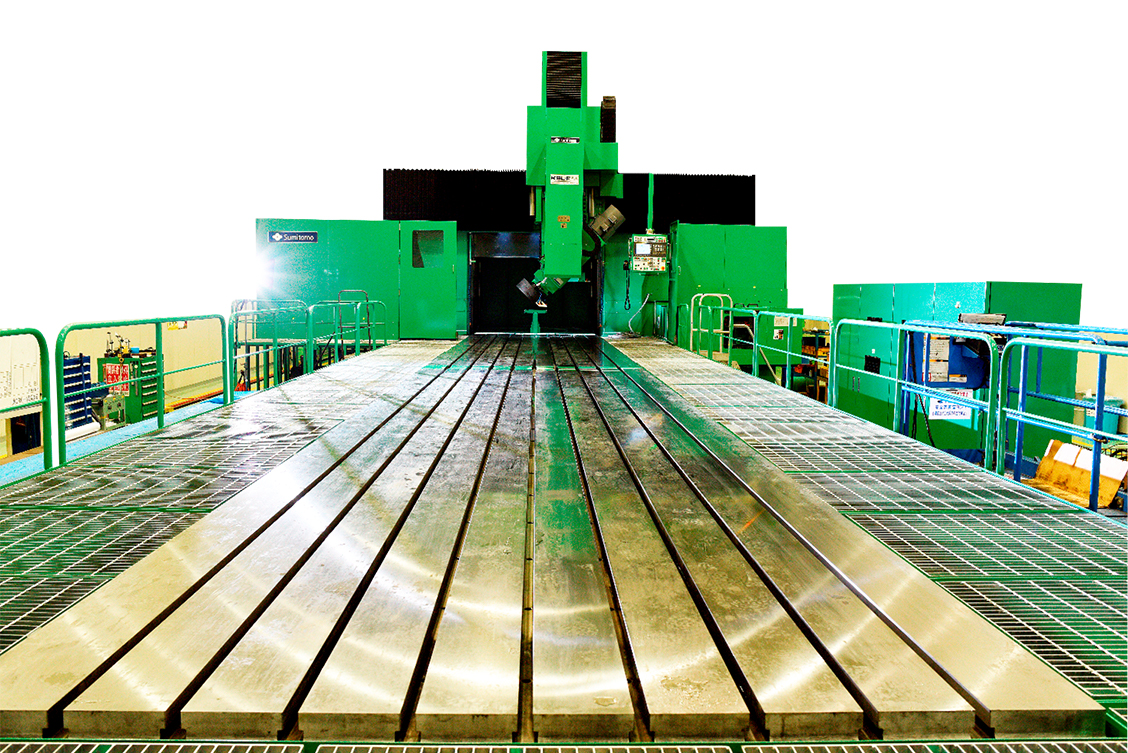

One-head and crossrail fixed construction realized to save 45% of space from usual double column type surface grinding machine with two heads.

So the horizontal stroke of grinding head is enough wide, that the work piece which is able to pass between the columns is possible to grind.

Reduce the grinding time

Standard table max. Speed is 35m/min and the spindle motor is 18.5kW, these specifications realize to reduce the rough grinding time.

Improve the grinding accuracy

Minimum increment system of the grinding head is 0.1μm and the sub-micron infeed is possible. In grinding of the thick or thin work piece, the head distortion is head back and high accurate grinding is realized.

Optimum model line-up to the required accuracy

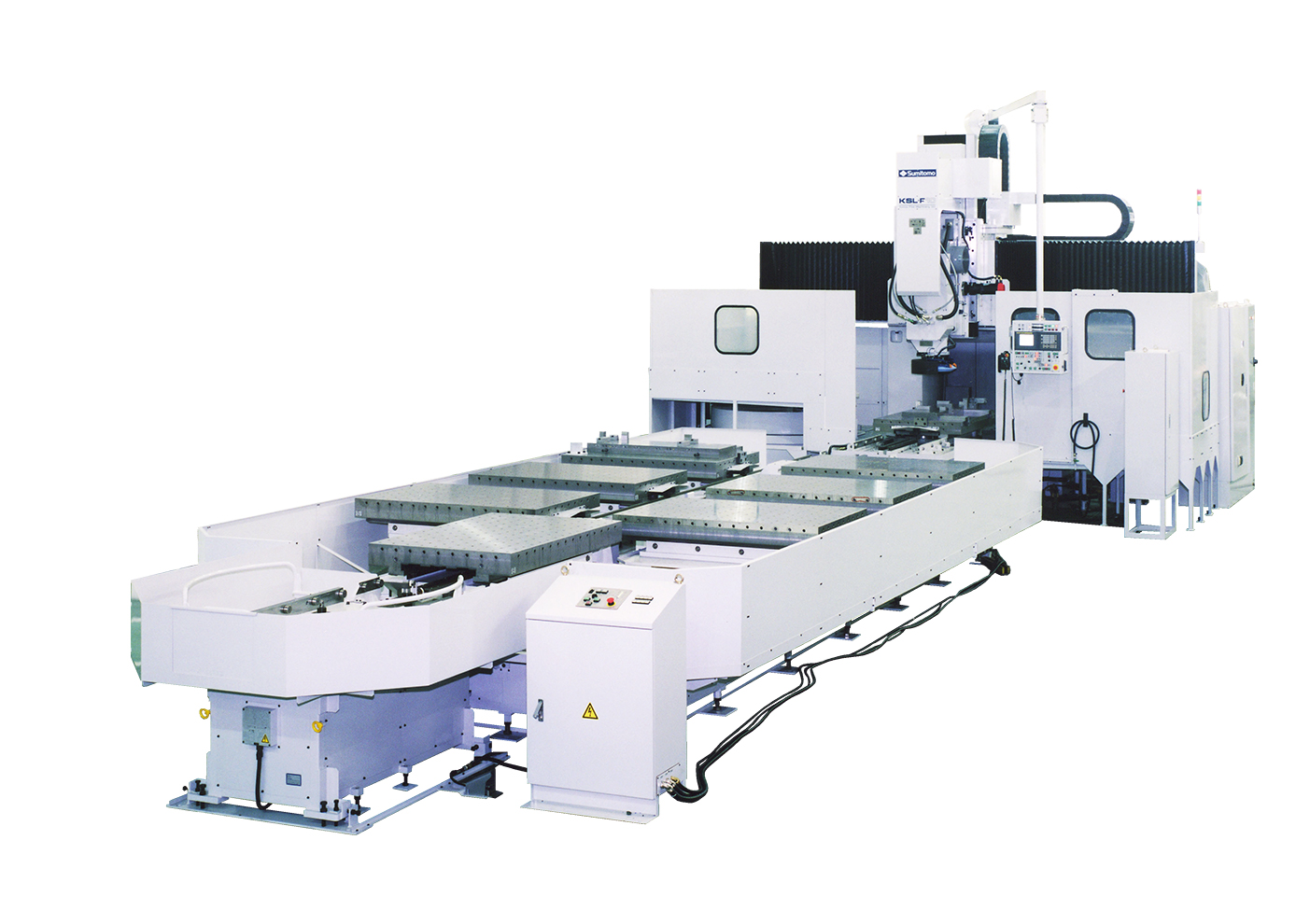

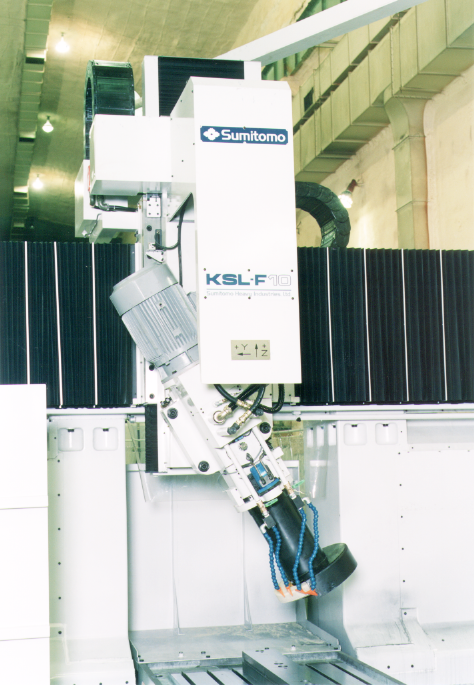

KSL-F

Standard model provides superior performance.

KSL-FX Series

Based on standard model with Hydrostatic slideways, horizontal & vertical grinding heads provides high accuracy

Case study

Product specifications

Optional accessories

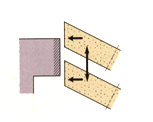

Double column Type(H.U type)

By equipping the horizontal axis with a vertical shaft (swivel), not only the upper surface but also the side surface, the groove groove etc. can be ground.

Vertical shaft

Vertical shaft specifications

| Spindle drive motor | kW | 2.2/3.7 |

|---|---|---|

| Grinding whee outer diameter | mm | 250 |

| Grinding whee internal diameter | mm | 101.6 |

| Grinding wheel width | mm | 25 |

| Spindle speed | min-1 | 1200〜2500 |

| Max. grinding height | mm | 525 |

Universal grinding head(U type) (8 rotary palette pool system)

- Reducing the time required for setting up and carrying the workpiece and in and out. Improves efficiency and saves labor.

- Various palette changers can be used to suit space and layout.

- The common use of palettes by the machining center 、machining center with five-face machining equipment to integrated factory automation.

Horizontal Spindle Head Type (H type)

Horizontal Spindle Head

- The spindle unit uses high rigidity and super precision bearings.

- Accurate vertical and horizontal feed of the grinding head is controlled by AC servo motors and precise ball screws.

- The slideways are coated with tow friction fluoro-plastic plates.

- Hydrostatic bearing grinding spindle(Optional accessories)

Pendant control box

The CNC control panel is built into a pendant control box, from which all operations of the machine are controlled. These include all manual operations such as grinding head feed, table driving and simple grinding cycle settings.

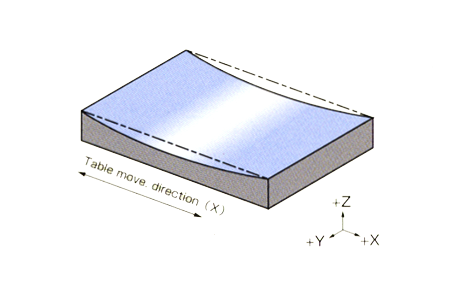

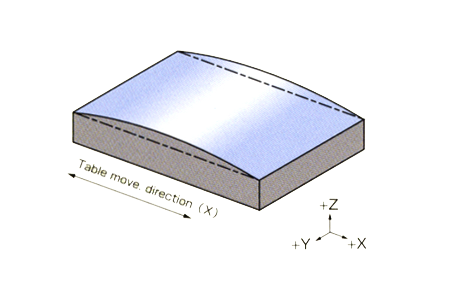

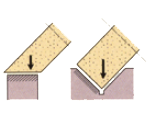

Convex/concave grinding device

Z axis convex/concave grinding (凹)

Z axis convex/concave grinding (凸)

Spherical surface convex/concave grinding (凸)

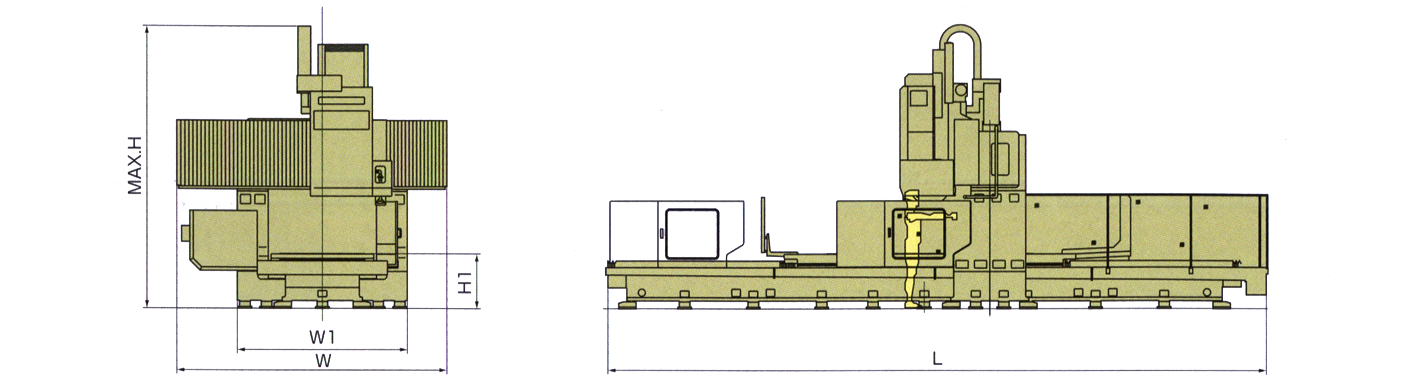

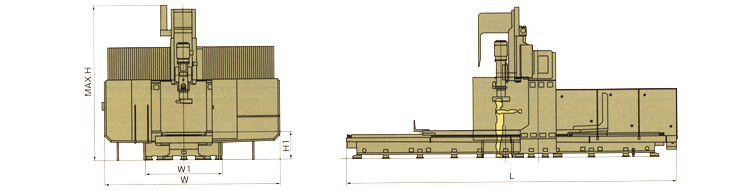

Dimension of machine size

Machine specification

| Machine Name | 10 type | 12 type | 15 type | 20 type | 22 type | 25 type | 30 type | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KSL-F(H) | 1020 | 1030 | 1220 | 1230 | 1520 | 1530 | 2040 | 2060 | 2230 | 2240 | 2540 | 2550 | 2560 | 3040 | 3050 | 3060 | |

| Grinding width | mm | 1000 | 1250 | 1500 | 2000 | 2200 | 2500 | 3000 | |||||||||

| Grinding length | mm | 2000 | 3000 | 2000 | 3000 | 2000 | 3000 | 4000 | 6000 | 3000 | 4000 | 4000 | 5000 | 6000 | 4000 | 5000 | 6000 |

| Max. table stroke | mm | 2700 | 3700 | 2700 | 3700 | 2700 | 3700 | 5000 | 7000 | 4000 | 5000 | 5000 | 6300 | 7300 | 5300 | 6300 | 7300 |

| Max. passage width | mm | 1300 | 1550 | 1800 | 2300 | 2500 | 3000 | 3300 | |||||||||

| Max. grinding height | mm | 700 | |||||||||||||||

| Table speed | m/min. | 4〜35 | 4〜30 | ||||||||||||||

| Max. weight of work pieces (include table) | kg | 5500 | 7000 | 6200 | 8000 | 7000 | 9000 | 12000 | 20000 | 9000 | 20000 | 16000 | 20000 | 24000 | 20000 | 25000 | 30000 |

| T-slot size (width×pitch×number) | mm | (24×145×7) | (24×160×8) | (24×180×8) | (24×210×9) | (24×220×9) | (24×250×10) | (28×250×12) | |||||||||

| Grinding whee outer diameter | mm | 610 | |||||||||||||||

| Grinding whee internal diameter | mm | 304.8 | |||||||||||||||

| Grinding wheel width | mm | 150 | |||||||||||||||

| Spindle drive motor | kW | 18.5 (22) | |||||||||||||||

| Spindle speed | min-1 | 950(600〜1200) | |||||||||||||||

| Minimum increment system | mm | 0.0001 | |||||||||||||||

| Vertical travel | mm | 740 | |||||||||||||||

| Vertical feed rate | mm/min. | 1〜2000 | |||||||||||||||

| Horizontal travel | mm | 1470 | 1720 | 1970 | 2350 | 2570 | 3170 | 3470 | |||||||||

| Horizontal feed rate | mm/min. | 1〜6000 | |||||||||||||||

| Width of machine body[W] | mm | 3700 | 3940 | 4200 | 4800 | 5000 | 5850 | 6150 | |||||||||

| Width of establishment[W1] | mm | 2240 | 2480 | 2740 | 3200 | 3440 | 4940 | 6500 | 6750 | ||||||||

| Length of machine body[L] | mm | 7650 | 9550 | 7650 | 9650 | 7650 | 9650 | 14200 | 18000 | 11600 | 13600 | 15000 | 17000 | 19000 | 15800 | 17800 | 20000 |

| Height of machine[H] | mm | 4100 | 4200 | 4900 | 5000 | 5250 | 5500 | ||||||||||

| Height of table surface[H1] | mm | 800 | 900 | 1295 | 1295 | 1390 | 1560 | ||||||||||

| Weight of machine | kg | 22000 | 25500 | 23500 | 28000 | 25000 | 29500 | 60000 | 69000 | 58000 | 61000 | 100000 | 105000 | 110000 | 115000 | 120000 | 125000 |

( )Inside is optional accessory

Standard accessories

- CNC control equipment

- FANUC FS-35i-B(Under F15)

- FANUC FS-32i-B(Over F20)

- Grinding wheel(Ф610×100)and flange

- Dressing device

- Splash cover

- Shower coolant device

- Work light(Under F15)

- Spark-on control device

- Automatic overload retracting device

- Wheel lifting tool

- Installation parts

- Levelling block

- anchor bolts

- sole plates

- bed-aligning bolts

- Power supply equipment

- Hydraulic oil cooler (refrigeration type)

- Leakage breaker

Optional accessories

- Coolant separator

- Magnetic coolant separator

- Magnetic coolant separator with paper filter

- Coolant temperature control device

- Magnetic chucks(various) and automatic neutrolator

- Inverter of spindle drive motor

- Spindle drive motor (22kW)

- Dynamic wheel balancing device(Manual type)

- Automatic measuring device of grinding allowance

- Grinding wheel flange

- Wheel balancing arbor

- Wheel balancing stand

- Cutting of T-slot on the table

- Coolant mist collector (with back full cover)

- Rotating lamp (3-color)

- Program storage length

・640m・1280m - NC control device

・FANUC FS-32i-B(over 20 series standard) - Automatic start or cut off device

- Convex/concave grinding device

- Special grinding soft

- Customers color

- Vertical axis (horizontal axis, heading, swivel function selectable)

- Head and Vertical · Left and Right Static Guide

- Spindle static pressure bearing

- SUS splash cover

- Integrated operation meter

Universal Spindle Head Type (U type)

Universal Head

- Rotation of the grinding head is indexed, precisely and automatically, in 5 degree steps (1 degree steps to special order) by the index coupling.

- The spindle unit uses high rigidity and super precision bearings.

- Accurate vertical and horizontal feed of the grinding head is controlled by AC servo motors and precise ball screws.

- The slideways are coated with tow friction fluoro-plastic plates.

Pendant control box

The CNC control panel is built into a pendant control box, from which all operations of the machine are controlled. These include all manual operations such as grinding head feed, table driving and simple grinding cycle settings.

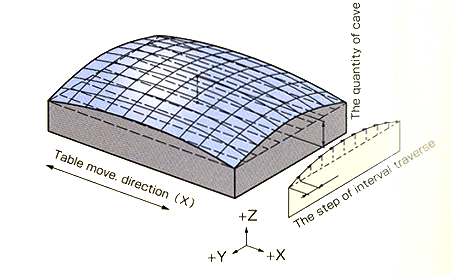

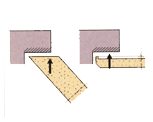

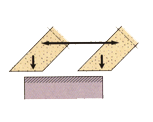

Grinding Pattern

Z Plunge

Z Plunge

Y Plunge

Y Travers

Z Travers

Dimension of machine size

Product specifications

| CNC control equipment | 10 type | 12 type | 15 type | 20 type | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| KSL-F(U) | 1020 | 1030 | 1220 | 1230 | 1520 | 1530 | 2040 | 2060 | |||

| Grinding width | mm | 1000 | 1250 | 1500 | 2000 | ||||||

| Grinding length | mm | 2000 | 3000 | 2000 | 3000 | 2000 | 3000 | 4000 | 6000 | ||

| Max. table stroke | mm | 2700 | 3700 | 2700 | 3700 | 2700 | 3700 | 5000 | 7000 | ||

| Max. passage width | mm | 1300 | 1550 | 1800 | 2200 | ||||||

| Max. grinding height | mm | 700(900) | |||||||||

| Table speed | m/min. | 4〜35 | 4〜30 | ||||||||

| Max. weight of work pieces (include table) | kg | 5500 | 7000 | 6200 | 8000 | 7000 | 9000 | 12000 | 20000 | ||

| T-slot size (width×pitch×number) | mm | (24×145×7) | (24×160×8) | (24×180×8) | (24×145×9) | ||||||

| Grinding whee outer diameter | mm | 510 | |||||||||

| Grinding whee internal diameter | mm | 177.8 | |||||||||

| Grinding wheel width | mm | 65 | |||||||||

| Spindle drive motor | kW | 15 (22)(30) | |||||||||

| Spindle speed | min-1 | 1200〜4500 | |||||||||

| Head rotation degree | ° | ±90° 5°pitch(1°pitch) | |||||||||

| Minimum increment system | mm | 0.0001 | |||||||||

| Vertical travel | mm | 740(940) | |||||||||

| Vertical feed rate | mm/min. | 1〜2000 | |||||||||

| Horizontal travel | mm | 2300 | 2550 | 2800 | 3300 | ||||||

| Horizontal feed rate | mm/min. | 1〜6000 | |||||||||

| Width of machine body[W] | mm | 4700 | 4940 | 5200 | 5700 | ||||||

| Width of establishment[W1] | mm | 2240 | 2480 | 2740 | 3200 | ||||||

| Length of machine body[L] | mm | 8650 | 10650 | 8650 | 10650 | 8650 | 10650 | 15200 | 19000 | ||

| Height of machine[H] | mm | 4100 | 4200 | 4900 | |||||||

| Height of table surface[H1] | mm | 800 | 900 | 1295 | |||||||

| Weight of machine | kg | 22000 | 25500 | 23500 | 28000 | 25000 | 29500 | 60000 | 69000 | ||

( )Is a special specification

Standard accessories

- CNC control equipment

・FANUC FS-32i-B - Grinding wheel(Ф610×100)and flange

- Dressing device

- Splash cover

- Shower coolant device

- Work light(Under F15)

- Spark-on control device

- Automatic overload retracting device

- Wheel lifting tool

- Installation parts

- Levellingblock

- anchor bolts

- sole plates

- bed-aligning bolts

- Power supply equipment

- Hydraulic oil cooler (refrigeration type)

- Leakage breaker

Optional accessories

- Coolant separator

- Magnetic coolant separator

- Magnetic coolant separator with paper filter

- Coolant temperature control device

- Magnetic chucks(various) and automatic neutrolator

- Inverter of spindle drive motor

- Dynamic wheel balancing device(Manual type)

- Automatic measuring device of grinding allowance

- Grinding wheel flange

- Extension arbor

- Wheel balancing arber

- Wheel balancing stand

- Cutting of T-slot on the table

- Coolant mist collector (with back full cover)

- Rotating lamp (3-color)

- Program storage length

・640m・1280m - Automatic start or cut off device

- Convex/concave grinding device

- Special grinding soft

- Customers color

- Head rotation degree 1°pitch

- SUS splash cover

- Integrated operation meter