Recommemded Industry and Workpiece

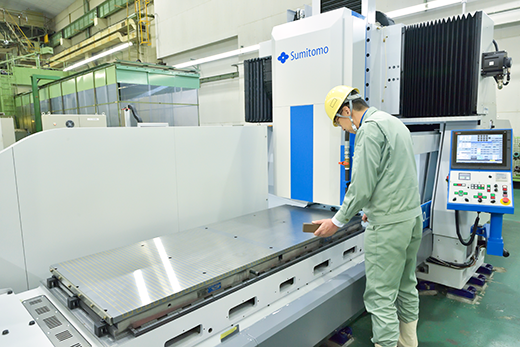

Grinding machine Liquid crystal and semiconductor parts Glass and ceramicsGrinding machine Various machine parts Various machine parts (Various flat plate parts)

Grinding machine Electrical and electric equipment parts Electrical equipment and tool parts

Grinding machine Molds Steel and mold plates

Grinding machine Automobiles/Automobile parts/Two-wheel parts Motor core molds and progressive molds for automobiles

Product characteristics

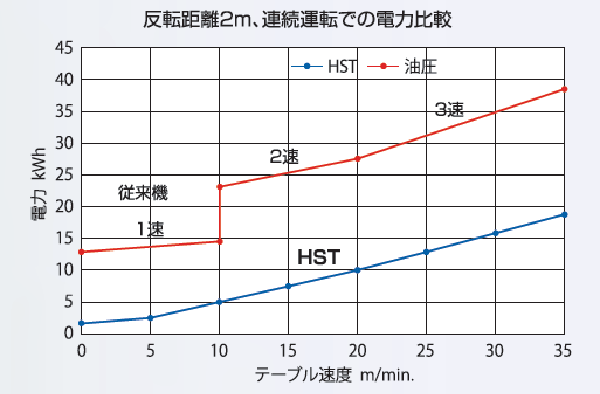

1.Equipped with energy-saving table driving device HST as a standard

- Reduced power consumption by over 50% compared to regular hydraulic units.

- The amount of oil used to operate the table is reduced to 10% and the regulations of the Fire Service Act have been met.

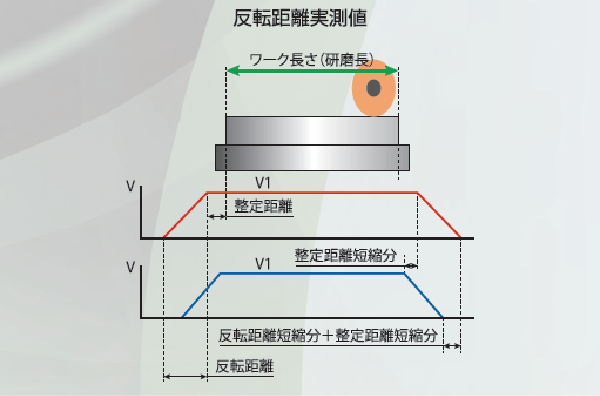

- The reverse distance has been reduced by 50% compared to regular machines, and both the turnaround time on the table and the grinding time have been shortened.

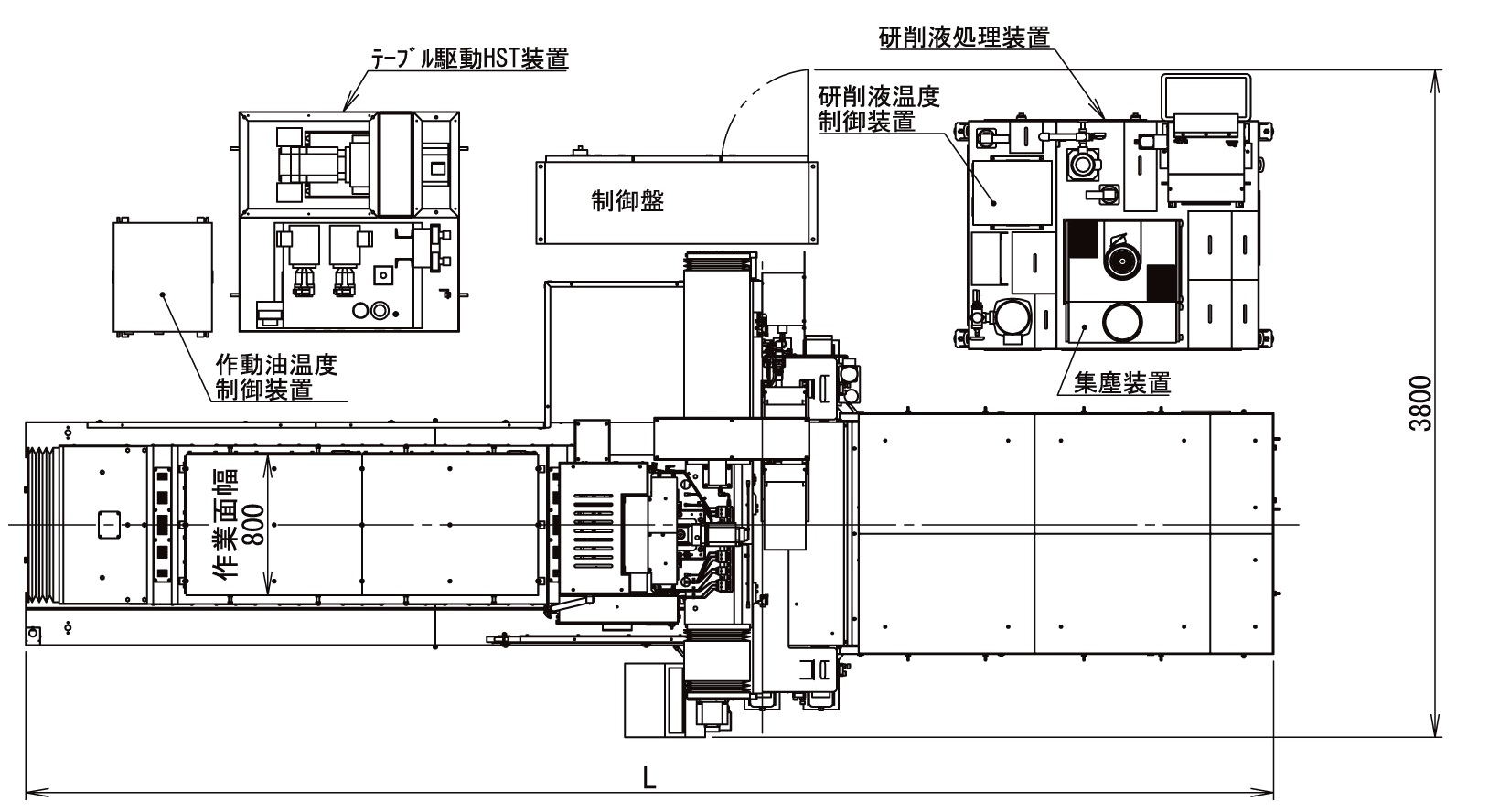

2.Least amount of space used for machines of the same category

- Used the latest optimization analysis technology to design a double column grinding machine with the least amount of space used among those of the same category.

- Optimum as a choice to upgrade to a cantilever grinding machine in the category of 800 mm width.

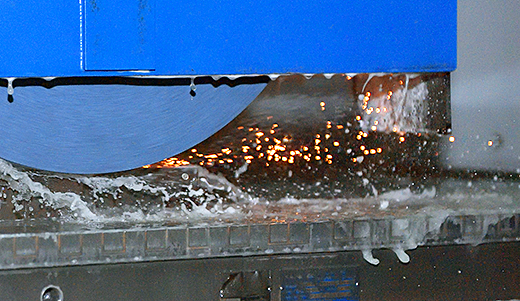

3.Compact grinding machine with high precision

- Adopted the newly developed principal spindle, which has high precision and rigidity and does not release much heat.

- The motor for the principal spindle uses 15 kW oil injection type AC spindle motor for low vibrations and minimized temperature changes.

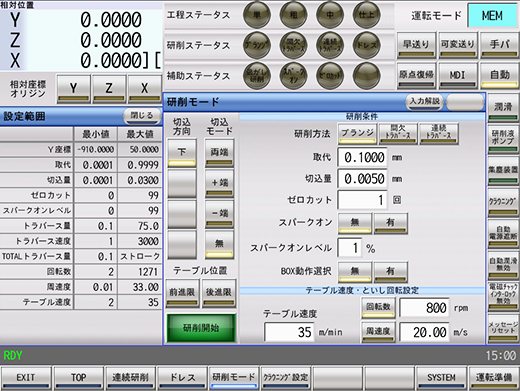

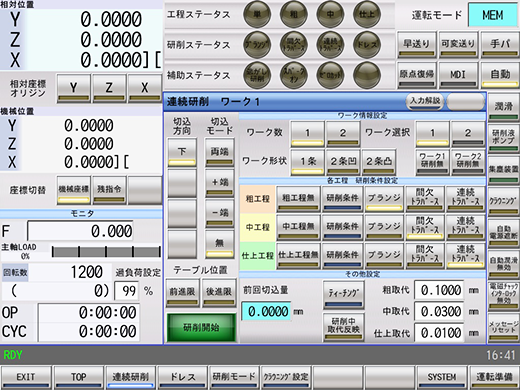

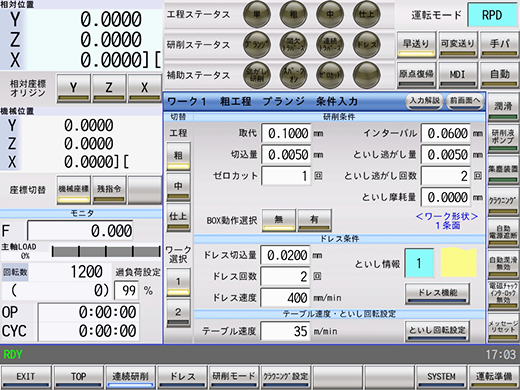

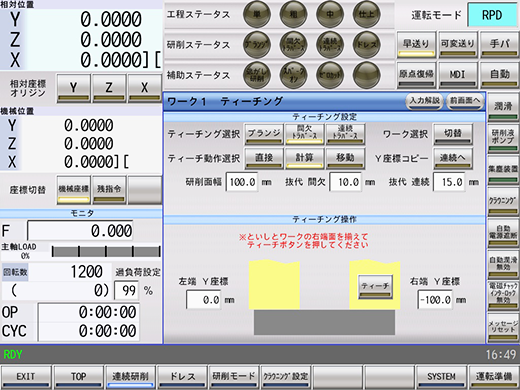

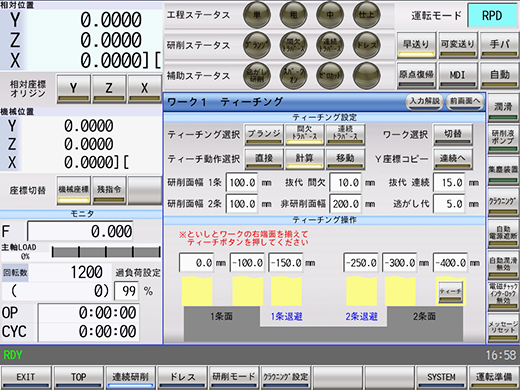

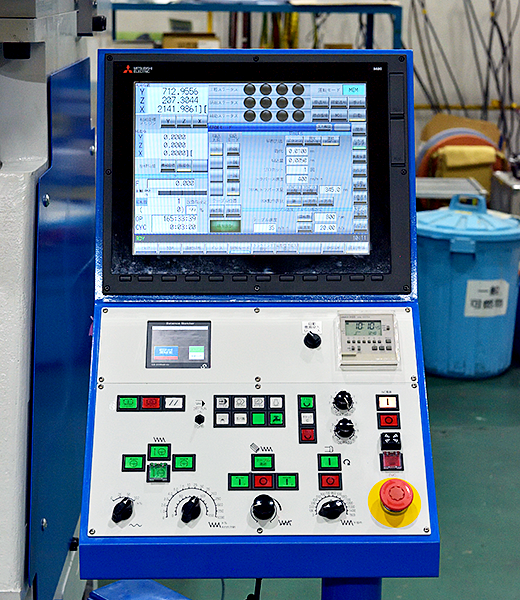

4.Easy to operate with a touch panel

- A touch panel type pendant control box is used as the control panel.

- The NC system has the latest Mitsubishi CNC.

- Provided with interactive screens that are easy to operate.

- Can run all three rough, intermediate and finish grinding in a batch.

- Can set a range of grinding conditions freely.

- Equipped with settings to achieve a higher surface quality as a standard.

Video

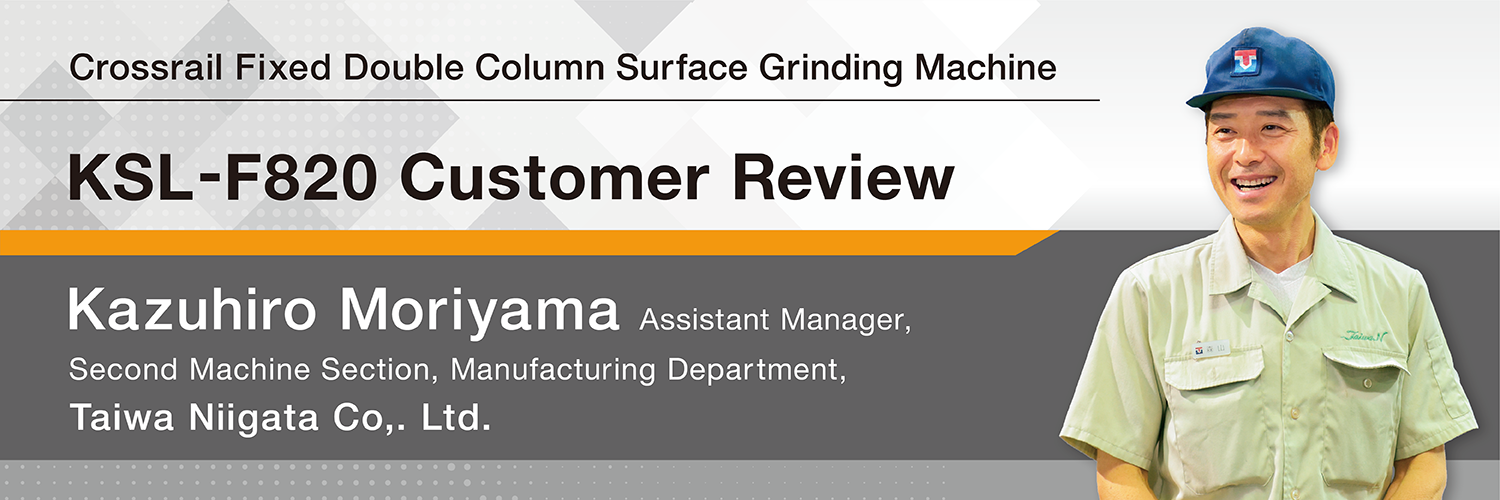

Case Study

Product specifications

Specifications

| Item | Unit | KSL-F8 | ||||

|---|---|---|---|---|---|---|

| 815 | 820 | 830 | ||||

| Capacity | Max. passage width of workpieces | mm | 1100 | |||

| Max. grinding height of workpieces | mm | 550 | ||||

| Size of table working space | Width | 800 | ||||

| Length | mm | 1500 | 2000 | 3000 | ||

| Max. permissible loaded weight ※Chuck weight (incl.) | kg | 2500 (750) |

3500 (1000) |

5000 (1500) |

||

| Feed rate | Table feed | m/min | 2~35 | |||

| Grinding wheel horizontal feed | mm/min | 1〜6000 | ||||

| Grinding wheel vertical feed | mm/min | 1〜2000 | ||||

| Grinding wheel head feed volume | Min. settings unit | mm | 0.0001 | |||

| Feed volume | mm | 0.0001〜0.9990 | ||||

| Spindle | Outer diameter x Width x Inner diameter | mm | 【Φ510~610】x【50~100】×Φ203.2 Grinding wheel width 50⇒No. 1 flat type 75⇒No. 5 concave type 100⇒No. 7 concave type |

|||

| Rotating speed | mm-1 | 500〜1500 | ||||

| Motor | kW | 15 | ||||

| Hydraulic tank | Tank capacity | L | 100 (Applied capacity:130L) | |||

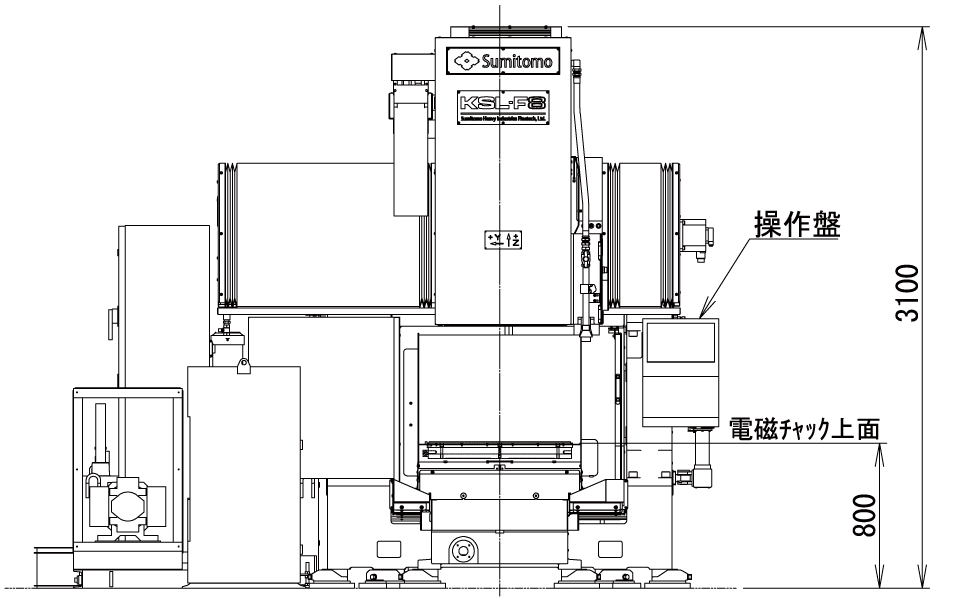

| Dimensions | Width | mm | 3850 | |||

| Height | mm | 3100 | ||||

| Length (L dimension) | mm | 6100 | 7100 | 9300 | ||

| Weight | According to standard specifications (excluding optional accessories) |

kg | 13500 | 14000 | 16500 | |

Accessories

Standard accessories

- Grinding wheel No. 5 concave type (Φ510x75xΦ203.2)

- Grinding wheel flange (with markings in increments of 5 degrees)

- Dressing device (table fixed surface dresser)

- Table driving device HST and hydraulic oil temperature control device

- Magnetic chucks and automatic attachment/release controller

- Spindle inverter control

- Spark-on control device

- Automatic overload retracting device

- Work light

- Signal tower (3 colors, lamp type)

- Wheel lifting tools, work tools, and installation parts

- Circuit breaker

Optional accessories

- Coolant processing equipment

Tank capacity: 600 L- Magnetic separator

- Ferrite

- Rare earth

- Magnetic separator with paper filter

- Coolant temperature control device

- Standard

- High-precision specifications

- Magnetic separator

- Grinding wheel flange (with markings in increments of 5 degrees)

- Dust collector

- Interactive wheel balancing device

- Automatic power start or cut off device

- Continuous grinding program

- Sliding door interlock on the operator’s side

Dimension of machine size