Proposals for preventive maintenance: Vertical Spindle Rotary Surface Grinding Machine – SVR Series

Please clean the machines after use every day so they will have a long life.

Chips and grinding wheel scraps from grinding work will adhere to the machine if they are left for a long period of time. In some cases, it may cause the machine to break down.

Simply cleaning the table with a hose after work every day can improve the machine life.

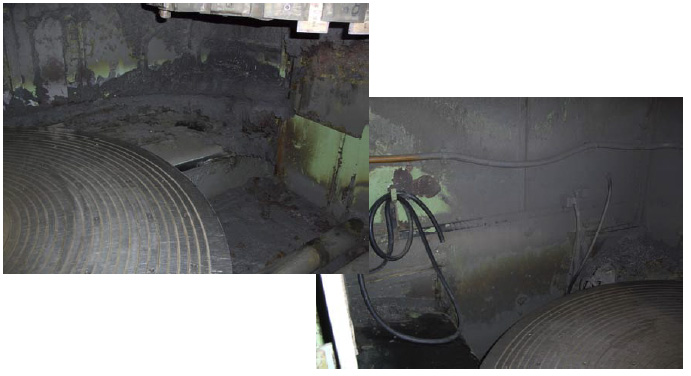

If left unattended like in the pictures below…

A few extra days will be needed just to scrape the machine clean during repair.

To reduce the machine stop time and repair fees, please clean the machines diligently every

day.

Do not forget to take safety precautions!

Self-diagnosis: Vertical Spindle Rotary Surface Grinding Machine SVR Series self-diagnosis menu

Every part of the machine is a consumable, so it may degrade and be damaged. Using the machine under such circumstances may cause it to break down.

To prevent machine breakdowns, use the self-diagnosis menu to determine if it is necessary to replace or repair parts.

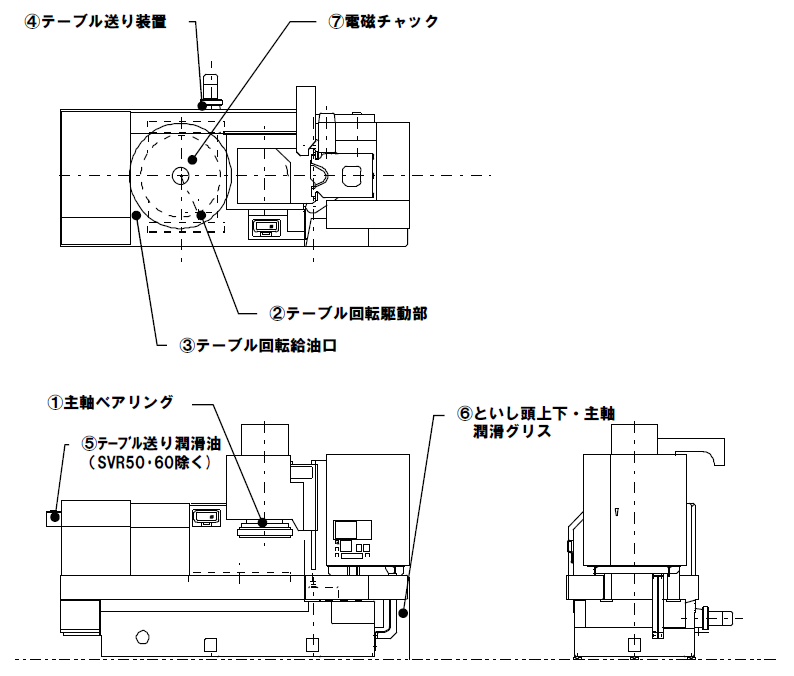

Inspection items

- Spindle bearing

- Table rotation drive

- Table rotation lubricating oil inlet

- Table feed equipment

- Table feed lubricating oil

- Grinding head vertical feed and spindle lubricating grease

- Magnetic chuck

If any of the following applies, the machine may be close to breaking down even if it is still running.First, please check each of the following items.

①Spindle bearing

- There is a strange noise when the Hydrostatic bearing spindle is rotating.

- It feels strange when it is rotated manually.

- There is a strange noise and vibrations when grinding a workpiece.

②Table rotation drive

③Table rotation lubricating oil inlet

- There is a strange noise and vibrations when the table is rotating.

- The motor thermal protection for table rotation falls off frequently.

- There is a strange noise from the Cyclo speed reducer for table rotation.

- The lubricating oil has not been changed for a while. (There are two inlets at the top and bottom.)

④Table feed equipment

- There is rattling during table foward/backward feed.

- Lubricating oil is not applied to the table front/rear feed slideway. (Inspect by touch.)

- Sludge has accumulated on the table front/rear feed slideway. (Inspect by touch.)

- The motor thermal protection for table front/rear feed falls off frequently.

- There is a strange noise from the cyclo reduction gear for table front/rear feed.

- Sludge has accumulated on the rack and pinion drive system. (Inspect by touch.)

⑤Table feed lubricating oil

⑥Grinding head vertical feed and principle spindle

lubricating grease

- The lubricating oil or grease does not decrease.

⑦Magnetic chuck

- There is a large scratch and dent on the top surface of the magnetic chuck.

- The adsorption power of the magnetic chuck has dropped compared to the beginning.

- The demagnetizing ability of the magnetic chuck has dropped compared to the beginning.

Abnormalities will start to appear before a machine breaks down. They may turn out to be minor issues if detected early, but they can cause secondary or tertiary breakdown if detected late, so it is important to take note of the condition of the machine when using it.

Please contact us if any of the above applies.

Updating control devices that cannot be repaired

Some control devices installed in our grinding machines cannot be repaired after the production has stopped and the applicable service period has passed, even if they are broken. If a part of the device breaks down, the entire device needs to be replaced.

Some devices may take a while to prepare, so there is a risk that they may need to be stopped for a long period of time after they break down. As preventive maintenance, we recommend updating control devices before that happens.

The list below is an example of such devices. We can offer solutions individually if you have questions or requests.

List of control devices that cannot be repaired

| Model | Uses | Name | Model | Manufacturer |

|---|---|---|---|---|

| SVR | Table rotation (including some spindle rotation) | Inverter | AF-500 series | Sumitomo Heavy Industries |

| AF-1200 series | ||||

| AF-3000 series | ||||

| AF-3100、3100α series | ||||

| SF-320 series | ||||

| HF-320 series | ||||

| HF-420 series | ||||

| FVR-G7S series | Fuji Electric | |||

| FVR-C9S series | ||||

| FREQROL-A200 series | Mitsubishi Electric | |||

| FREQROL-A500L series | ||||

| HI series | Keyence | |||

| Table feed | Inverter | SF-320 series | Sumitomo Heavy Industries | |

| HI series | Keyence | |||

| Control device for magnetic chucks | Contourator | NS2-5FC、NS2-10FC | Fuji Jikoh | |

| NS2-5FE、NS2-5FET18 | ||||

| NS2-10GT1 | ||||

| NS4-10T4 |