Proposals for higher productivity: CNC Double column Surface Grinding Machine – KSL Series

Interactive dynamic wheel balancing device

Pursuit of complete ease-of-use and low cost

The definitive grinding wheel balance

Balancer for precision grinding

Field Balancer For High-Precision

SB-8001GS

(Max 10,000min-1)

Comes in an A4-sized trunk case!

The grinding wheel is rotated on the machine and measured, so it brings the following

benefits:

・Corrects any unbalance in the grinding wheel as a whole.

・Stabilizes the grinding resistance and improves the quality of the ground surface.

Features

- Extremely high measurement accuracy (resolution of 0.001 μm).

- Easy to operate because it is 2 or 3 weight selection type

- Easy to see with a large LED display.

- Weight angles and displacements are displayed in real-time.

- Compact, lightweight, and low cost (stored in a trunk case).

New functions

- Improved measurement accuracy with the installation of the latest

microcomputer.

The measurement accuracy for unbalanced vibration is higher compared to regular machines, making it possible to correct unbalances with a high precision at a high decreasing rate. - The angle scale (increase/decrease in the direction of the rotation) can be

selected.

The direction of the angle scale of the rotating device can be changed with one touch. - Equipped with a backup function.

Even when the power is turned off, the system remembers the influence coefficient and various settings (such as the number of correction plane and angle scale), eliminating the hassle of reconfiguring the system again.

Warning system menu

Coolant flow monitoring system

It is very dangerous to perform grinding when there is no coolant, because it may lead to fire accidents.

The surface grinding machines that we produce are equipped with a high-sensitivity flow sensor, which monitors the coolant flow while grinding. If the coolant stops flowing, the system can raise an alarm and stop the machine.

This eliminates the risk of fire accidents and operators can use the machine safely.

Current status

Has no flow sensor or has a paddle-type flow sensor

The paddle-type breaks down easily,

so it may not be functioning properly.

Manufactured by Yamatake:FS4-3J and FS7-4J

Our proposal

Installation of a high-sensitivity flow sensor

- The sensitivity is easy to adjust.

- Easy to maintain.

- Long life.

Manufactured by Ifm electronic: SI5000

| Target model | KPL/KSL/KSL-F | KSH |

|---|---|---|

| Target production number | FFK380〜TTK422 | FFH359〜TTH399 |

Why don’t you update your NC control device for a stable operation?

- Reduce the failure rate and increase the operating rate by updating your current NC control device.

- Our stable service parts supply system allows customers to use our products without worry even in the case of an emergency.

- The control panel has been renewed as well, so the operability has improved greatly.

- The ladder screen can be displayed, which reduces the time taken to track the cause of troubles.

Case Study of NC update

(1) KPL-2050N manufactured in 1987

· Updated in October 2007

· Updated the NC from FANUC FS12M to FANUC FS16iM.

(2) KPL-2070N manufactured in 1981

· Updated in December 2008

· Updated the NC from NEDAC to FANUC FS31iM.

Magnet separator

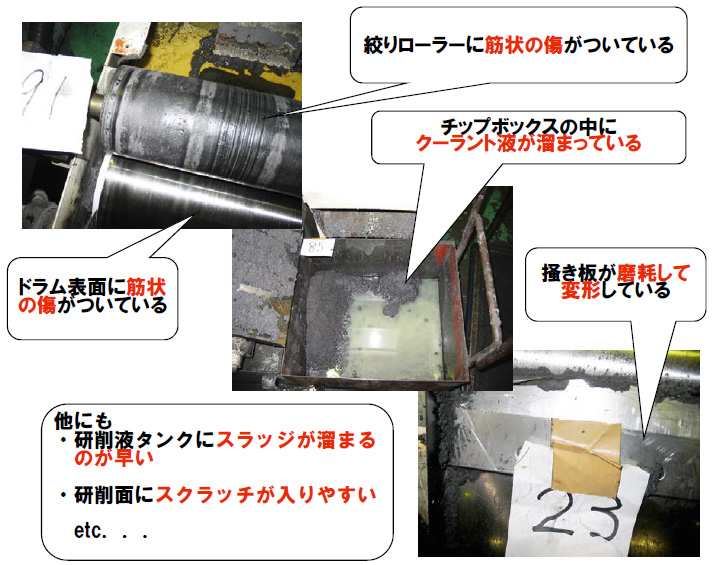

Look at the back of the machine. Does your magnet separator look like the pictures shown below?

If so, why don’t you try upgrading to Sumitomo Heavy Industries Finetech’s FINE MAG, our best performing magnet separator?

- Equipped with a magnet drum with the most optimum design based on our unique

analytical technology for magnetic fields.

It has a high filtering performance that can be maintained for a long period of time. - Special hardening treatment for the magnetic drum surface.

The drum surface will not be scratched semi-permanently. - Adopted the forced drive method for the squeeze roller to prevent

slipping.

The sludge is squeezed strongly with stable pressure.